- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 is an advanced solution for reshaping and grinding tools made of metal and steel. Designed with high precision in mind, it integrates automatic operations and a functional five-axis servo motor system for efficient and reliable grinding tasks. Its versatile design ensures compatibility with a wide range of industrial tools, making it essential for various manufacturing sectors.

This CNC tool grinding machine supports flexible configurations, allowing manufacturers to handle complex tool geometries with ease. Its robust build and automatic features improve operational efficiency, making it suitable for high-demand production environments. From reshaping intricate tools to maintaining consistency in tool quality, the CTG-X7 is a trusted choice for precision grinding.

With cutting-edge technology and a focus on custom configurations, the CTG-X7 delivers exceptional results. Its high-speed spindle and integrated cooling system ensure optimal tool performance while preventing overheating during extended use. The machine offers a compact design combined with industrial-grade durability, making it a reliable and long-term investment for manufacturers.

| Xaxis route: | 460mm |

| Xaxis route: | 800mm |

| Xaxis route: | 320mm |

| Xaxis route: | 360° |

| Xaxis route: | 00 |

| Control motor type: | servo motorx5 axis |

| Spindle power: | 16kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1900*2400*2500mm/6000kg |

This high precision CNC tool grinding machine is ideal for industries such as aerospace, automotive, and medical manufacturing. As a functional and automatic grinding solution, it ensures accurate reshaping of tools used in industrial applications. For manufacturers seeking advanced technology and reliable performance, the CTG-X7 delivers on all fronts.

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 is equipped with an advanced 5-axis servo motor system. This technology ensures precise grinding and reshaping of tools with complex geometries. It is designed to meet the needs of industrial manufacturers seeking high accuracy and consistent tool quality.

The machine features an optional robotic arm for automatic tool handling, which operates independently of the grinding cabinet. This automatic functionality saves time by allowing simultaneous loading and grinding. Additionally, the automatic honing system sharpens tools for enhanced performance and extended durability, making it an efficient choice for industrial applications.

The CTG-X7 offers a choice between a granite base with a DD motor or a cast iron base with a worm gear and lead screw. These customizable options provide flexibility to suit different production environments, ensuring stable and reliable operations for grinding metal and steel tools.

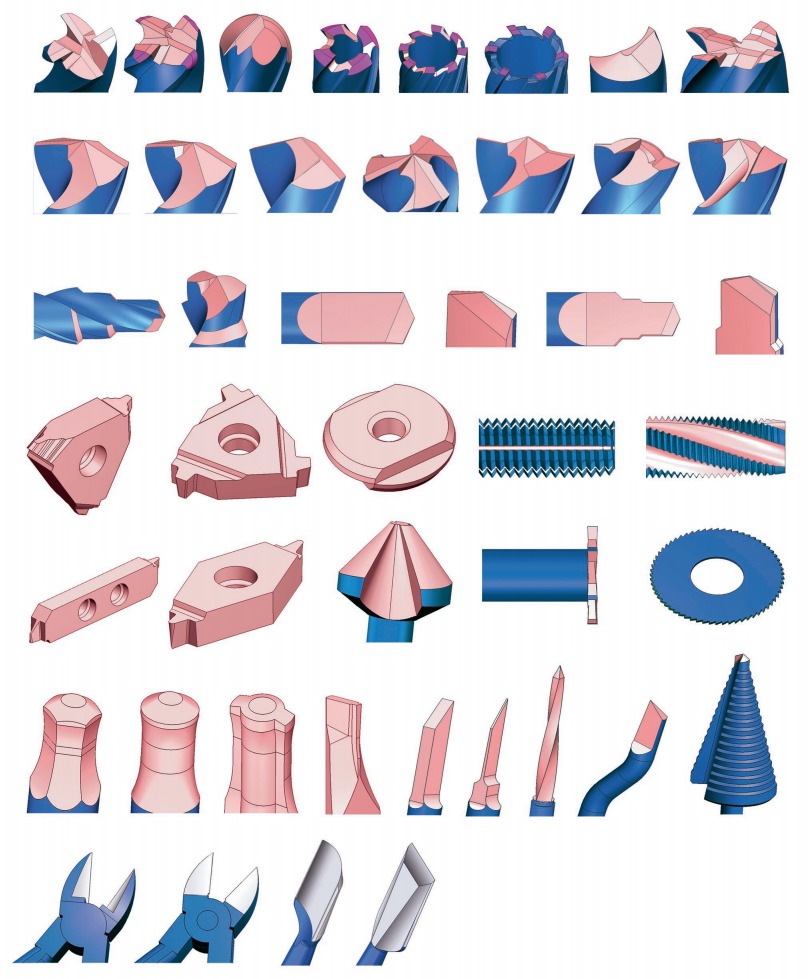

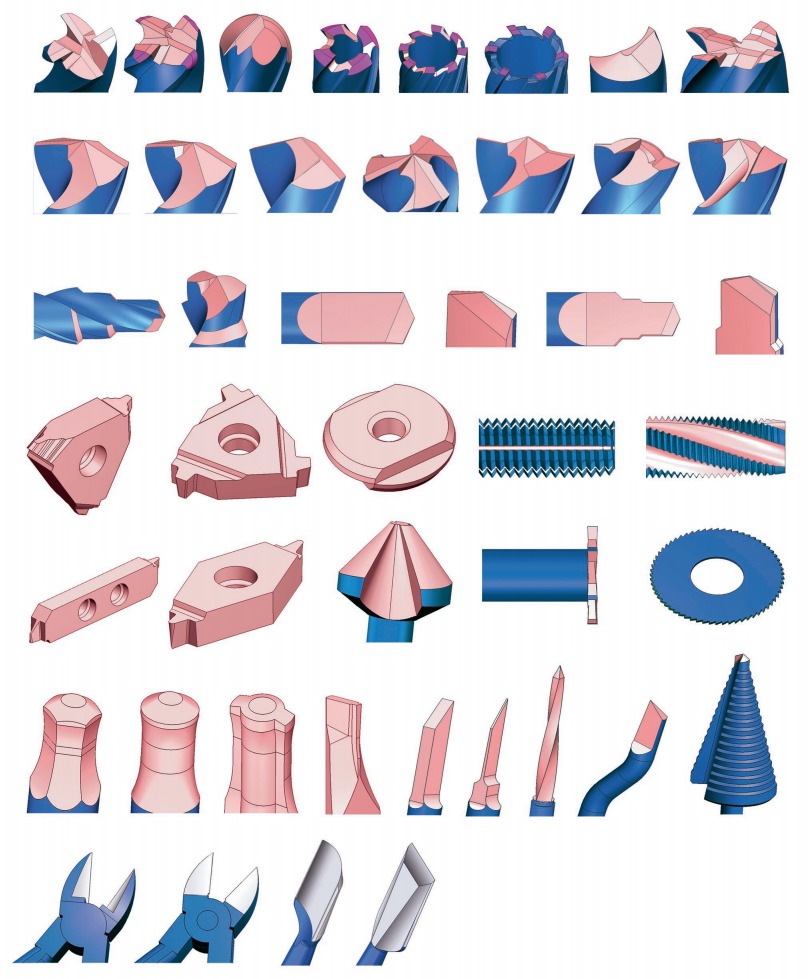

This functional CNC tool grinding machine supports a wide range of tools, including end mills, taps, ball-end mills, reamers, and medical instruments. It accommodates tools with diameters from 1 mm to 25 mm and lengths up to 400 mm. The versatile design makes it suitable for industries such as aerospace, automotive, medical manufacturing, and general metalworking.

The machine includes custom-developed software with a 3D graphical interface, enabling easy and intuitive programming. This user-friendly interface eliminates the need for specialized programming personnel, allowing operators to manage multiple machines and reduce labor costs.

Aerospace: Ensures precise grinding of tools for aircraft components.

Automotive: Produces high-precision tools for engines and transmissions.

Medical Manufacturing: Meets the exacting standards required for surgical tools and implants.

Metalworking: Maintains and reshapes tools for steel and metal production.

Mold Fabrication: Delivers consistent results in tool reshaping for mold production.

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 combines advanced technology, automatic features, and high precision to provide industrial manufacturers with a reliable solution for tool grinding and reshaping. Its versatility and functionality make it a valuable investment for a variety of applications.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 is an advanced solution for reshaping and grinding tools made of metal and steel. Designed with high precision in mind, it integrates automatic operations and a functional five-axis servo motor system for efficient and reliable grinding tasks. Its versatile design ensures compatibility with a wide range of industrial tools, making it essential for various manufacturing sectors.

This CNC tool grinding machine supports flexible configurations, allowing manufacturers to handle complex tool geometries with ease. Its robust build and automatic features improve operational efficiency, making it suitable for high-demand production environments. From reshaping intricate tools to maintaining consistency in tool quality, the CTG-X7 is a trusted choice for precision grinding.

With cutting-edge technology and a focus on custom configurations, the CTG-X7 delivers exceptional results. Its high-speed spindle and integrated cooling system ensure optimal tool performance while preventing overheating during extended use. The machine offers a compact design combined with industrial-grade durability, making it a reliable and long-term investment for manufacturers.

| Xaxis route: | 460mm |

| Xaxis route: | 800mm |

| Xaxis route: | 320mm |

| Xaxis route: | 360° |

| Xaxis route: | 00 |

| Control motor type: | servo motorx5 axis |

| Spindle power: | 16kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1900*2400*2500mm/6000kg |

This high precision CNC tool grinding machine is ideal for industries such as aerospace, automotive, and medical manufacturing. As a functional and automatic grinding solution, it ensures accurate reshaping of tools used in industrial applications. For manufacturers seeking advanced technology and reliable performance, the CTG-X7 delivers on all fronts.

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 is equipped with an advanced 5-axis servo motor system. This technology ensures precise grinding and reshaping of tools with complex geometries. It is designed to meet the needs of industrial manufacturers seeking high accuracy and consistent tool quality.

The machine features an optional robotic arm for automatic tool handling, which operates independently of the grinding cabinet. This automatic functionality saves time by allowing simultaneous loading and grinding. Additionally, the automatic honing system sharpens tools for enhanced performance and extended durability, making it an efficient choice for industrial applications.

The CTG-X7 offers a choice between a granite base with a DD motor or a cast iron base with a worm gear and lead screw. These customizable options provide flexibility to suit different production environments, ensuring stable and reliable operations for grinding metal and steel tools.

This functional CNC tool grinding machine supports a wide range of tools, including end mills, taps, ball-end mills, reamers, and medical instruments. It accommodates tools with diameters from 1 mm to 25 mm and lengths up to 400 mm. The versatile design makes it suitable for industries such as aerospace, automotive, medical manufacturing, and general metalworking.

The machine includes custom-developed software with a 3D graphical interface, enabling easy and intuitive programming. This user-friendly interface eliminates the need for specialized programming personnel, allowing operators to manage multiple machines and reduce labor costs.

Aerospace: Ensures precise grinding of tools for aircraft components.

Automotive: Produces high-precision tools for engines and transmissions.

Medical Manufacturing: Meets the exacting standards required for surgical tools and implants.

Metalworking: Maintains and reshapes tools for steel and metal production.

Mold Fabrication: Delivers consistent results in tool reshaping for mold production.

The Custom 5-Axis CNC Tool Grinding Machine CTG-X7 combines advanced technology, automatic features, and high precision to provide industrial manufacturers with a reliable solution for tool grinding and reshaping. Its versatility and functionality make it a valuable investment for a variety of applications.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|