- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a cutting-edge solution for industrial tool grinding. It is engineered to deliver high precision and efficiency, making it an essential piece of equipment for industries that rely on metal and steel tools. This advanced machine is designed to meet the demands of modern manufacturing processes while ensuring consistent grinding quality.

This 5-axis grinding machine features a servo motor system that allows for precise control over grinding operations, ensuring tools are processed to exact specifications. With a high spindle power and maximum RPM, the machine is capable of handling a wide variety of grinding tasks, including complex geometries. Its robust design and compact size make it ideal for industrial environments where reliability and performance are priorities.

The machine supports custom configurations, allowing users to adapt it to specific tool requirements. It works seamlessly with tools of varying lengths and diameters, providing flexibility for different machining needs. Whether you are a manufacturer or supplier, this functional and efficient tool grinding machine optimizes productivity while reducing downtime.

| SPECIFICATION | CTG-520S/526S/536S | CTG-52OS P/526SP Pneumatic Style |

| Xaxis route | 300mm | 300mm |

| Yaxis route: | 160mm | 160mm |

| Zaxis route: | 160mm | 160mm |

| Caxisroute: | -190~45° | -190~45° |

| Aaxis route: | oo | oo |

| Control motortype: | servo motor x5 axis | servo motor x5 axis |

| Spindle power: | 2.5kw | 2.5kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Toolmaximum length: | 330mm | 220mm |

| Dimension/Weight: | 1300*1200*2000mm/1720kg | 1300*1200*2000mm/1720kg |

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a state-of-the-art solution for creating and sharpening precision tools. Engineered for industrial use, the machine combines functional design with advanced technology to meet the complex demands of modern manufacturing. Below are its key features and applications:

This 5-axis CNC tool grinding machine is equipped with custom-designed software featuring an intuitive 3D graphical interface. Operators can easily visualize tool geometries, fine-tune parameters, and execute grinding tasks without requiring advanced programming skills.

The machine incorporates automated wheel dressing and tool polishing functions. These features ensure consistent grinding results and refined tool surfaces, reducing manual intervention and promoting high precision in industrial applications.

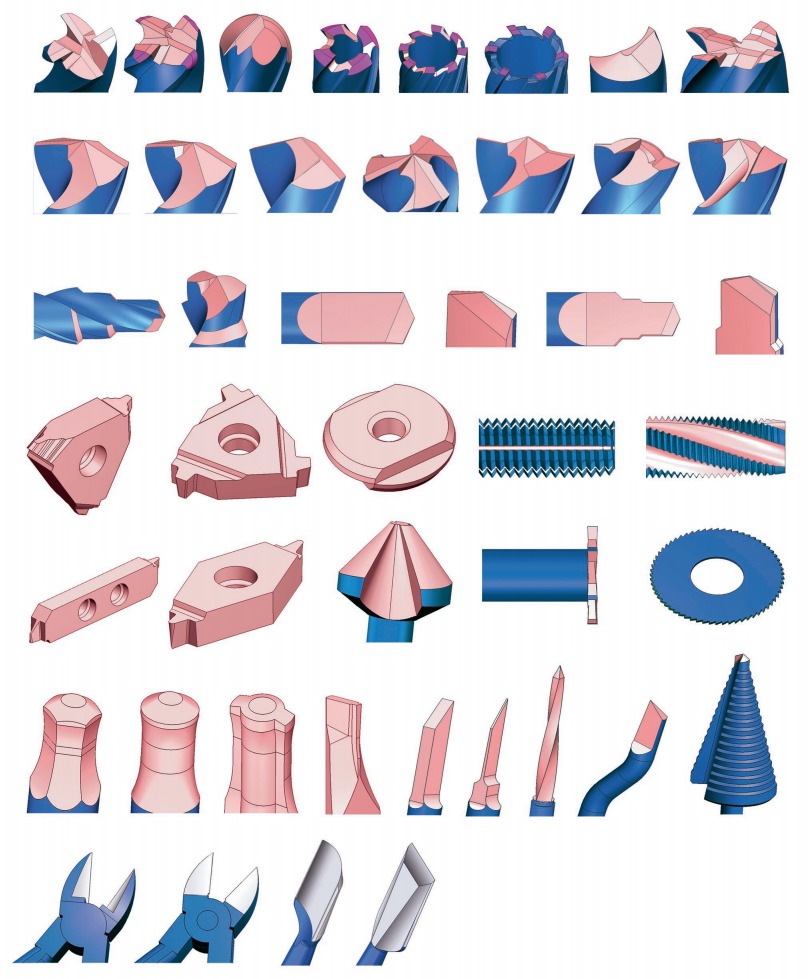

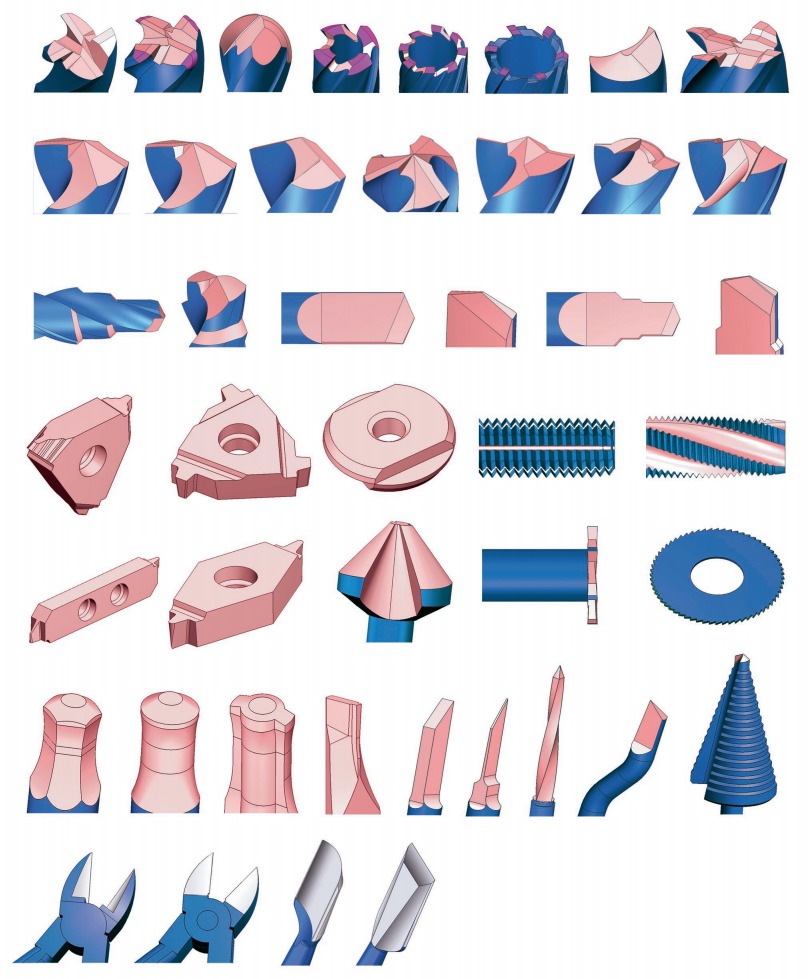

The machine supports a wide range of tool types and sizes, including ball-end mills, taps, drills, engraving tools, and medical instruments. With tool holding diameters ranging from 1-20mm (CTG-520S) to 1-36mm (CTG-536S), it is highly flexible for different machining needs.

The advanced 5-axis linkage design allows for the production and re-sharpening of complex tools and accessories. This ensures precision grinding for metal and steel tools used in various industries, including aerospace, automotive, and mold-making.

The machine is engineered for efficiency. Its automation features, combined with a user-friendly interface, allow one operator to manage multiple machines. This reduces labor costs while maintaining high-quality results for industrial tool grinding.

The CTG-520S/526S/536S/520SP/526SP is widely used in industries requiring precision tools. This includes applications in medical device manufacturing, CNC machining centers, and steel tool production. Its durability and advanced features make it an essential machine for industries working with metal tools.

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a versatile, high-precision solution for manufacturers. It delivers consistent results, improves productivity, and supports a wide range of grinding applications. This machine is ideal for meeting the growing demand for precision and efficiency in industrial tool grinding processes.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

Q1: What tools can the 5-Axis CNC Tool Grinding Machine process?

A1: It can process end mills, drills, taps, engraving tools, reamers, and medical instruments.

Q2: Is the machine suitable for grinding complex geometries?

A2: Yes, the advanced 5-axis linkage ensures precision for complex tool shapes and designs.

Q3: Does the machine support automated grinding processes?

A3: Yes, it includes automated wheel dressing and tool polishing for consistent and precise results.

Q4: Can the machine handle multiple tool sizes?

A4: Yes, it accommodates various tool diameters, ranging from 1mm to 36mm, depending on the model.

Q5: How does the machine improve efficiency in tool grinding?

A5: Its automation features and user-friendly interface allow one operator to manage multiple machines.

Q6: Is the machine suitable for industrial applications?

A6: Yes, it is designed for high-precision grinding in industries like aerospace, automotive, and medical manufacturing.

Q7: What materials can the machine grind?

A7: It is ideal for grinding tools made of metal, steel, and other durable materials used in machining.

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a cutting-edge solution for industrial tool grinding. It is engineered to deliver high precision and efficiency, making it an essential piece of equipment for industries that rely on metal and steel tools. This advanced machine is designed to meet the demands of modern manufacturing processes while ensuring consistent grinding quality.

This 5-axis grinding machine features a servo motor system that allows for precise control over grinding operations, ensuring tools are processed to exact specifications. With a high spindle power and maximum RPM, the machine is capable of handling a wide variety of grinding tasks, including complex geometries. Its robust design and compact size make it ideal for industrial environments where reliability and performance are priorities.

The machine supports custom configurations, allowing users to adapt it to specific tool requirements. It works seamlessly with tools of varying lengths and diameters, providing flexibility for different machining needs. Whether you are a manufacturer or supplier, this functional and efficient tool grinding machine optimizes productivity while reducing downtime.

| SPECIFICATION | CTG-520S/526S/536S | CTG-52OS P/526SP Pneumatic Style |

| Xaxis route | 300mm | 300mm |

| Yaxis route: | 160mm | 160mm |

| Zaxis route: | 160mm | 160mm |

| Caxisroute: | -190~45° | -190~45° |

| Aaxis route: | oo | oo |

| Control motortype: | servo motor x5 axis | servo motor x5 axis |

| Spindle power: | 2.5kw | 2.5kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Toolmaximum length: | 330mm | 220mm |

| Dimension/Weight: | 1300*1200*2000mm/1720kg | 1300*1200*2000mm/1720kg |

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a state-of-the-art solution for creating and sharpening precision tools. Engineered for industrial use, the machine combines functional design with advanced technology to meet the complex demands of modern manufacturing. Below are its key features and applications:

This 5-axis CNC tool grinding machine is equipped with custom-designed software featuring an intuitive 3D graphical interface. Operators can easily visualize tool geometries, fine-tune parameters, and execute grinding tasks without requiring advanced programming skills.

The machine incorporates automated wheel dressing and tool polishing functions. These features ensure consistent grinding results and refined tool surfaces, reducing manual intervention and promoting high precision in industrial applications.

The machine supports a wide range of tool types and sizes, including ball-end mills, taps, drills, engraving tools, and medical instruments. With tool holding diameters ranging from 1-20mm (CTG-520S) to 1-36mm (CTG-536S), it is highly flexible for different machining needs.

The advanced 5-axis linkage design allows for the production and re-sharpening of complex tools and accessories. This ensures precision grinding for metal and steel tools used in various industries, including aerospace, automotive, and mold-making.

The machine is engineered for efficiency. Its automation features, combined with a user-friendly interface, allow one operator to manage multiple machines. This reduces labor costs while maintaining high-quality results for industrial tool grinding.

The CTG-520S/526S/536S/520SP/526SP is widely used in industries requiring precision tools. This includes applications in medical device manufacturing, CNC machining centers, and steel tool production. Its durability and advanced features make it an essential machine for industries working with metal tools.

The Advanced 5-Axis CNC Tool Grinding Machine CTG-520S/526S/536S/520SP/526SP is a versatile, high-precision solution for manufacturers. It delivers consistent results, improves productivity, and supports a wide range of grinding applications. This machine is ideal for meeting the growing demand for precision and efficiency in industrial tool grinding processes.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

Q1: What tools can the 5-Axis CNC Tool Grinding Machine process?

A1: It can process end mills, drills, taps, engraving tools, reamers, and medical instruments.

Q2: Is the machine suitable for grinding complex geometries?

A2: Yes, the advanced 5-axis linkage ensures precision for complex tool shapes and designs.

Q3: Does the machine support automated grinding processes?

A3: Yes, it includes automated wheel dressing and tool polishing for consistent and precise results.

Q4: Can the machine handle multiple tool sizes?

A4: Yes, it accommodates various tool diameters, ranging from 1mm to 36mm, depending on the model.

Q5: How does the machine improve efficiency in tool grinding?

A5: Its automation features and user-friendly interface allow one operator to manage multiple machines.

Q6: Is the machine suitable for industrial applications?

A6: Yes, it is designed for high-precision grinding in industries like aerospace, automotive, and medical manufacturing.

Q7: What materials can the machine grind?

A7: It is ideal for grinding tools made of metal, steel, and other durable materials used in machining.