- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is an advanced and automatic grinding solution designed for reshaping and sharpening complex cutting tools. Built with high precision in mind, this machine is suitable for grinding tools made of metal and steel, ensuring excellent performance across various industrial applications.

Equipped with a custom-designed five-axis servo motor system, this machine provides simultaneous multi-angle grinding for maximum accuracy. Its precision grinding capability ensures consistent tool quality, making it ideal for industries requiring exact specifications.

The CTG-X6/X5 features an automatic operation system combined with a user-friendly CNC interface, allowing for seamless programming and efficient tool grinding. Additionally, the machine's rigid construction and high-speed spindle are designed to handle continuous industrial use, minimizing downtime and maximizing productivity.

This high precision grinding machine supports the reshaping of tools such as end mills, drills, and cutters. Its advanced cooling system prevents overheating, ensuring that grinding efficiency and tool durability are maintained. Furthermore, the integrated automatic tool measurement system guarantees accurate tool dimensions, making it an essential choice for manufacturers seeking reliable grinding solutions for steel and metal tools.

Below are the detailed specifications for both the CTG-X6 and CTG-X5 models of this advanced grinding machine:

| SPECIFICATION | CTG-X6 | CTG-X5 |

| Xaxis route: | 770 mm | 710mm |

| Yaxis route: | 340 mm | 312mm |

| Zaxis route: | 225mm | 170mm |

| Caxis route: | -190~45° | -190~45° |

| Aaxis route: | 0 | 0 |

| Control motor type: | servo motor ×5 axis | servo motorx5 axis |

| Spindle power: | 7.5kw | 2.5kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Dimension/Weight: | 1820*1850*2100mm/3100kg | 1600*1680*1950mm/2300kg |

This industrial-grade Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is an excellent option for manufacturers looking to enhance machining efficiency. With its automatic system, custom configurations, and precision grinding capabilities, it is a versatile choice for reshaping steel and metal tools used in high-demand industries. This machine is a reliable investment for businesses aiming to achieve consistent and high-quality tool maintenance.

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is equipped with an advanced five-axis CNC system, ensuring high precision for grinding and reshaping complex cutting tools. It allows simultaneous multi-angle grinding, making it suitable for tools requiring exceptional accuracy and consistency.

This machine features an automatic tool handling system with a custom-designed software interface. The intuitive 3D graphical interface simplifies programming, while the automatic tool holder and arm enhance operational efficiency. These features ensure smooth grinding processes for a variety of tools.

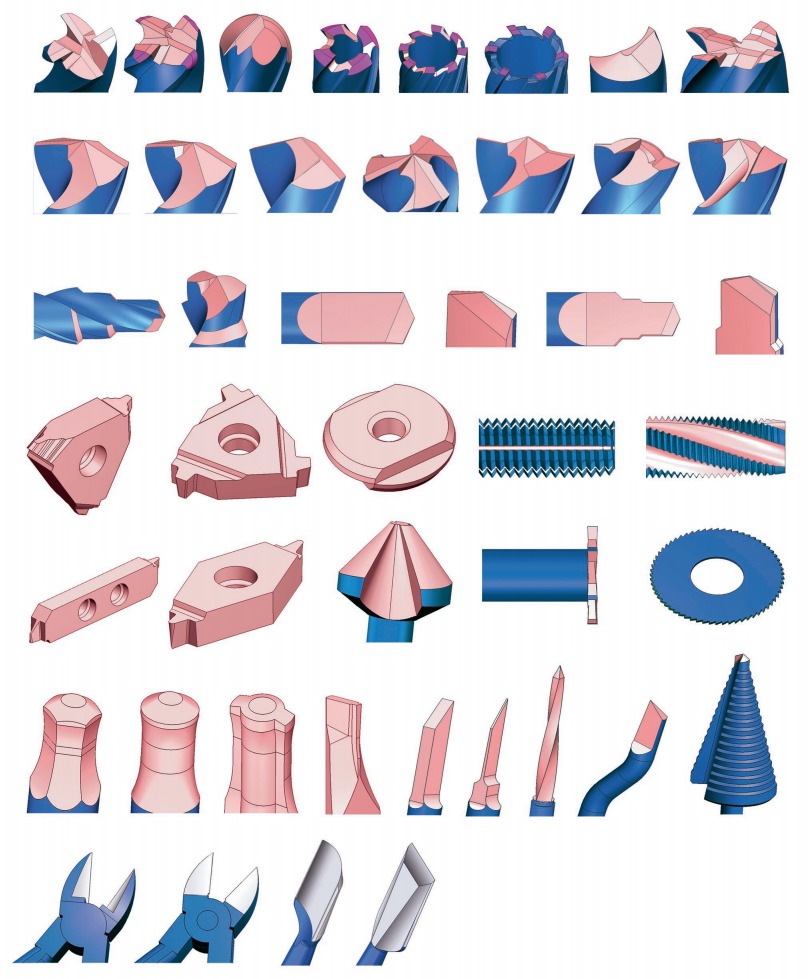

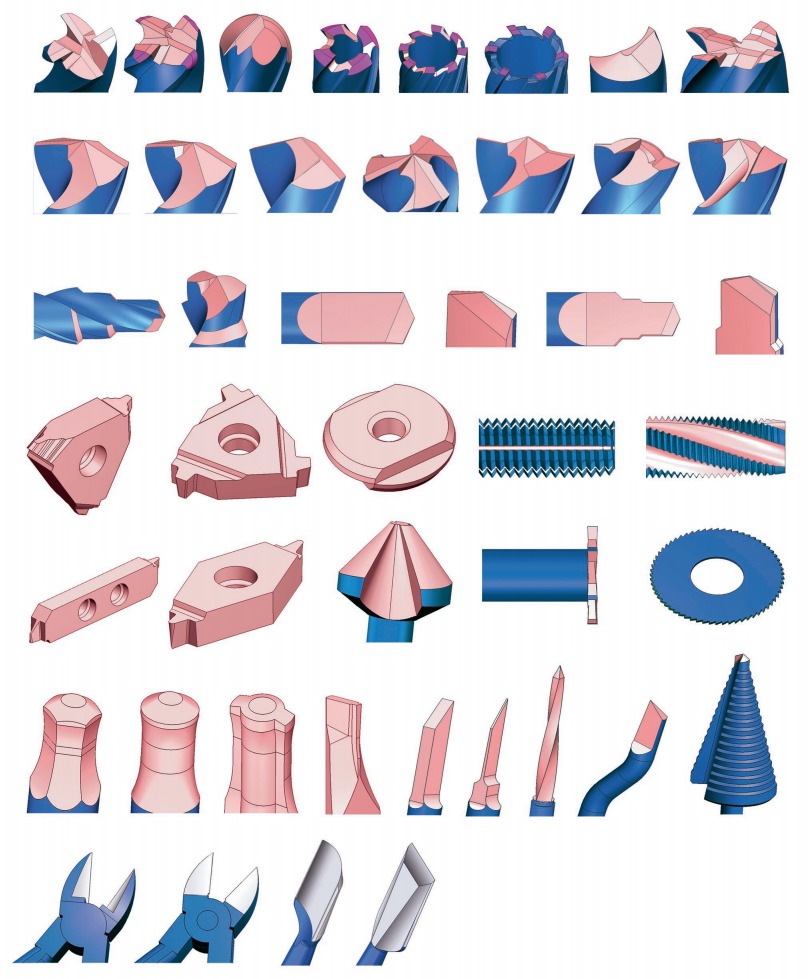

The CTG-X6/X5 supports a wide range of tools, including end mills, ball-end mills, taps, drills, gun drills, and medical instruments. It handles tools with diameters between 1 mm and 25 mm, making it ideal for industries such as aerospace, automotive, medical, and mold manufacturing.

The machine delivers exceptional performance for grinding metal and steel tools. It accommodates tools up to 400 mm in length and 230 mm in flute length, ensuring reliable results for long cutting tools used in industrial production.

To maintain tool quality, the CTG-X6/X5 integrates a high-precision cooling system that prevents overheating during grinding. Additionally, the automatic dual A-axis tool measurement system guarantees accurate reshaping and grinding, reducing the need for manual adjustments.

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is widely used in industries requiring precision and efficiency:

Aerospace: Reshapes cutting tools for producing high-precision aerospace components.

Automotive: Ensures accurate grinding of cutting tools used in engines and transmissions.

Medical: Meets the strict precision standards for grinding surgical tools and implants.

Mold Manufacturing: Enhances the reshaping of tools used for creating molds with high accuracy.

General Metalworking: Maintains cutting tools for steel and metal production processes.

The CTG-X6/X5 is a reliable solution for manufacturers aiming to optimize productivity and maintain tool quality. Its advanced features, automatic functionality, and versatile applications make it a valuable asset for industrial tool grinding and reshaping needs.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

Q1: What tools can the 5-Axis CNC Tool Grinding Machine CTG-X6/X5 handle?

A1: It supports end mills, ball-end mills, taps, drills, gun drills, and medical instruments with diameters from 1 mm to 25 mm.

Q2: How does the advanced cooling system improve grinding performance?

A2: The cooling system prevents overheating during grinding, ensuring precision and extending the lifespan of metal and steel tools.

Q3: Is the 5-Axis CNC Tool Grinding Machine suitable for industrial use?

A3: Yes, it is built for heavy-duty industrial applications, offering reliable performance for reshaping complex tools in multiple industries.

Q4: Can I use this machine for custom tool grinding?

A4: Yes, the machine includes custom-designed software with a user-friendly 3D graphical interface for flexible and precise tool grinding.

Q5: What industries benefit from using this CNC grinding machine?

A5: It is widely used in aerospace, automotive, medical, mold-making, and metalworking industries requiring high-precision tools.

Q6: Does the machine support automatic tool handling?

A6: Yes, it includes an automatic tool holder and robotic arm for seamless loading and grinding, improving operational efficiency.

Q7: How does this machine ensure high precision in grinding?

A7: Its advanced five-axis CNC system and automatic measurement features guarantee accurate reshaping and high-quality grinding results.

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is an advanced and automatic grinding solution designed for reshaping and sharpening complex cutting tools. Built with high precision in mind, this machine is suitable for grinding tools made of metal and steel, ensuring excellent performance across various industrial applications.

Equipped with a custom-designed five-axis servo motor system, this machine provides simultaneous multi-angle grinding for maximum accuracy. Its precision grinding capability ensures consistent tool quality, making it ideal for industries requiring exact specifications.

The CTG-X6/X5 features an automatic operation system combined with a user-friendly CNC interface, allowing for seamless programming and efficient tool grinding. Additionally, the machine's rigid construction and high-speed spindle are designed to handle continuous industrial use, minimizing downtime and maximizing productivity.

This high precision grinding machine supports the reshaping of tools such as end mills, drills, and cutters. Its advanced cooling system prevents overheating, ensuring that grinding efficiency and tool durability are maintained. Furthermore, the integrated automatic tool measurement system guarantees accurate tool dimensions, making it an essential choice for manufacturers seeking reliable grinding solutions for steel and metal tools.

Below are the detailed specifications for both the CTG-X6 and CTG-X5 models of this advanced grinding machine:

| SPECIFICATION | CTG-X6 | CTG-X5 |

| Xaxis route: | 770 mm | 710mm |

| Yaxis route: | 340 mm | 312mm |

| Zaxis route: | 225mm | 170mm |

| Caxis route: | -190~45° | -190~45° |

| Aaxis route: | 0 | 0 |

| Control motor type: | servo motor ×5 axis | servo motorx5 axis |

| Spindle power: | 7.5kw | 2.5kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Dimension/Weight: | 1820*1850*2100mm/3100kg | 1600*1680*1950mm/2300kg |

This industrial-grade Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is an excellent option for manufacturers looking to enhance machining efficiency. With its automatic system, custom configurations, and precision grinding capabilities, it is a versatile choice for reshaping steel and metal tools used in high-demand industries. This machine is a reliable investment for businesses aiming to achieve consistent and high-quality tool maintenance.

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is equipped with an advanced five-axis CNC system, ensuring high precision for grinding and reshaping complex cutting tools. It allows simultaneous multi-angle grinding, making it suitable for tools requiring exceptional accuracy and consistency.

This machine features an automatic tool handling system with a custom-designed software interface. The intuitive 3D graphical interface simplifies programming, while the automatic tool holder and arm enhance operational efficiency. These features ensure smooth grinding processes for a variety of tools.

The CTG-X6/X5 supports a wide range of tools, including end mills, ball-end mills, taps, drills, gun drills, and medical instruments. It handles tools with diameters between 1 mm and 25 mm, making it ideal for industries such as aerospace, automotive, medical, and mold manufacturing.

The machine delivers exceptional performance for grinding metal and steel tools. It accommodates tools up to 400 mm in length and 230 mm in flute length, ensuring reliable results for long cutting tools used in industrial production.

To maintain tool quality, the CTG-X6/X5 integrates a high-precision cooling system that prevents overheating during grinding. Additionally, the automatic dual A-axis tool measurement system guarantees accurate reshaping and grinding, reducing the need for manual adjustments.

The Functional 5-Axis CNC Tool Grinding Machine CTG-X6/X5 is widely used in industries requiring precision and efficiency:

Aerospace: Reshapes cutting tools for producing high-precision aerospace components.

Automotive: Ensures accurate grinding of cutting tools used in engines and transmissions.

Medical: Meets the strict precision standards for grinding surgical tools and implants.

Mold Manufacturing: Enhances the reshaping of tools used for creating molds with high accuracy.

General Metalworking: Maintains cutting tools for steel and metal production processes.

The CTG-X6/X5 is a reliable solution for manufacturers aiming to optimize productivity and maintain tool quality. Its advanced features, automatic functionality, and versatile applications make it a valuable asset for industrial tool grinding and reshaping needs.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

Q1: What tools can the 5-Axis CNC Tool Grinding Machine CTG-X6/X5 handle?

A1: It supports end mills, ball-end mills, taps, drills, gun drills, and medical instruments with diameters from 1 mm to 25 mm.

Q2: How does the advanced cooling system improve grinding performance?

A2: The cooling system prevents overheating during grinding, ensuring precision and extending the lifespan of metal and steel tools.

Q3: Is the 5-Axis CNC Tool Grinding Machine suitable for industrial use?

A3: Yes, it is built for heavy-duty industrial applications, offering reliable performance for reshaping complex tools in multiple industries.

Q4: Can I use this machine for custom tool grinding?

A4: Yes, the machine includes custom-designed software with a user-friendly 3D graphical interface for flexible and precise tool grinding.

Q5: What industries benefit from using this CNC grinding machine?

A5: It is widely used in aerospace, automotive, medical, mold-making, and metalworking industries requiring high-precision tools.

Q6: Does the machine support automatic tool handling?

A6: Yes, it includes an automatic tool holder and robotic arm for seamless loading and grinding, improving operational efficiency.

Q7: How does this machine ensure high precision in grinding?

A7: Its advanced five-axis CNC system and automatic measurement features guarantee accurate reshaping and high-quality grinding results.