- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 is engineered for high precision tool grinding. Designed for industrial use, it delivers exceptional performance for grinding metal and steel tools. This machine is tailored to support various tool sizes and shapes, making it a functional and versatile solution for manufacturers.

Equipped with a 5-axis servo motor system, the machine ensures accurate and efficient grinding. Its advanced design offers high spindle power and RPM, enabling smooth operations across different applications. The machine's compact structure and robust build make it suitable for demanding industrial environments.

The grinder is ideal for custom configurations, meeting unique production requirements. It supports a wide clamping diameter range, allowing flexibility in tool grinding. This advanced machine is perfect for industries like aerospace, automotive, and medical manufacturing that demand precision tooling solutions.

Whether you need to produce or maintain complex tools, this machine guarantees consistent and high-quality results. Its user-friendly interface simplifies operation, reducing the need for extensive training. Manufacturers can rely on this machine to improve productivity and enhance tool performance.

| SPECIFICATION | CTG-526 | CTG-536 |

| Xaxis route: | 380mm | 380mm |

| Yaxis route: | 300mm | 300mm |

| Zaxisroute: | 160mm | 160mm |

| Caxisroute: | -190~45° | -190~45° |

| Aaxis route: | 00 | 00 |

| Control motor type: | servo motor x5 axis | servo motor x5 axis |

| Spindle power: | 7.5 kw | 7.5 kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Clamp diameter range: | 1~25mm | 1~36mm |

| Dimension/Weight: | 1650*1550*2000mm/1500kg | 1650*1550*2000mm/1500kg |

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 combines advanced technology with functional design for grinding tools with precision. It is a reliable choice for manufacturers seeking versatile and efficient grinding solutions.

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 is designed for industrial tool grinding with a focus on precision and efficiency. Its advanced features and versatility make it suitable for a wide range of applications. Below are its key highlights and usage scenarios:

The machine is equipped with custom software and a 3D graphical interface. This makes it user-friendly, allowing operators to visualize tool geometries and make precise adjustments. It streamlines the workflow and reduces setup time.

The advanced 5-axis CNC linkage ensures functional grinding of complex tool shapes. It is capable of producing high-precision tools and re-sharpening worn-out tools with consistency, making it ideal for industrial use.

This machine features automatic wheel dressing and tool polishing, ensuring consistent grinding quality. These functionalities enhance tool durability and reduce manual intervention, saving time and resources.

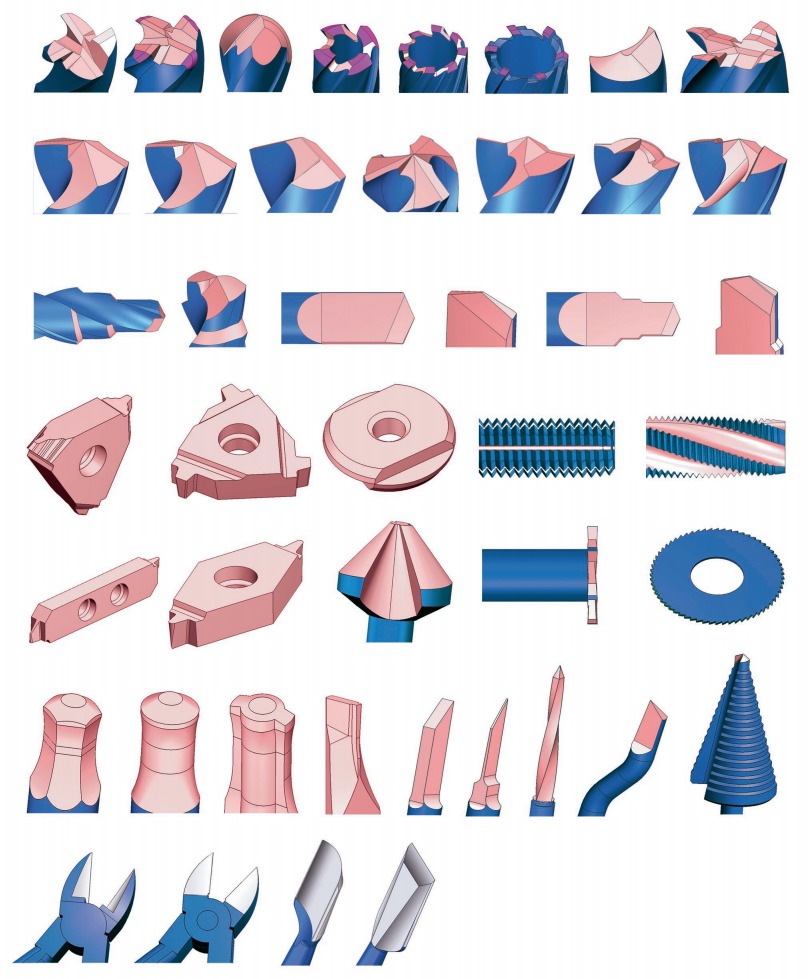

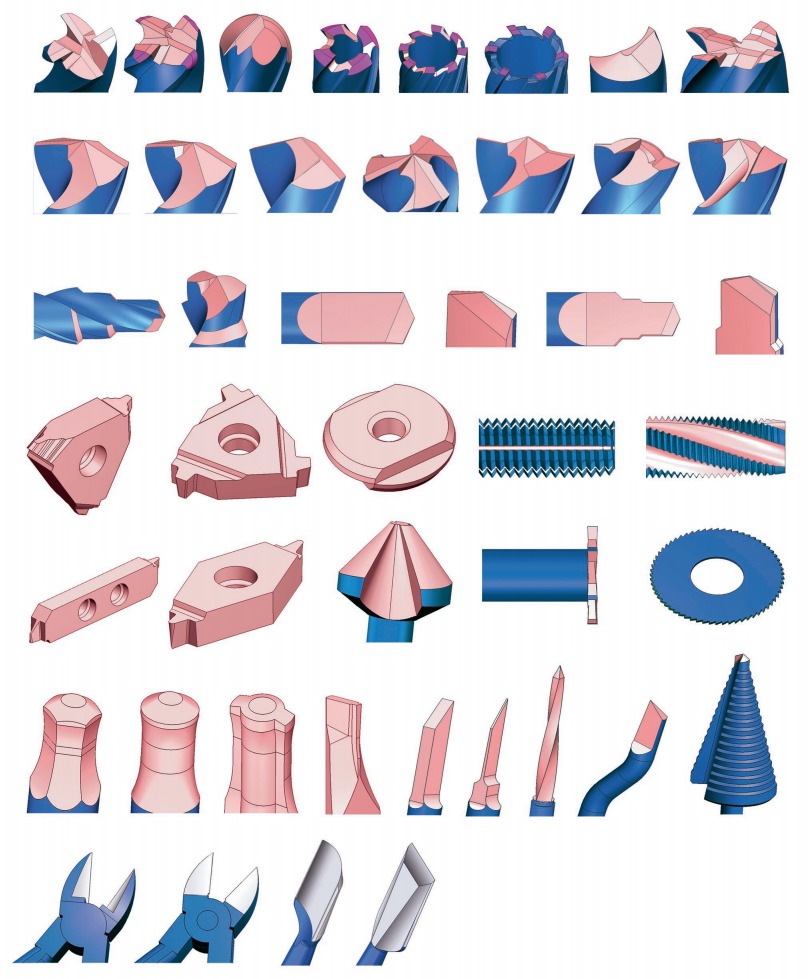

The machine is compatible with various tools, including end mills, ball-end mills, drills, taps, engraving tools, and medical instruments. Its ability to process tools made of metal and steel makes it a preferred choice for aerospace, automotive, and medical manufacturing.

The CTG-526/536 supports tool lengths up to 330mm and flute lengths of 150mm. Its wide clamping diameter range accommodates different tool sizes, ensuring flexibility in production and regrinding.

With robust construction and advanced components, the machine is designed for industrial environments. It supports high spindle RPM and reliable servo motors, ensuring smooth operations and consistent results.

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 combines advanced technology with custom functionality, meeting the demands of industries that require precision grinding. Its versatility and efficiency make it a valuable asset for manufacturers seeking to optimize their operations.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 is engineered for high precision tool grinding. Designed for industrial use, it delivers exceptional performance for grinding metal and steel tools. This machine is tailored to support various tool sizes and shapes, making it a functional and versatile solution for manufacturers.

Equipped with a 5-axis servo motor system, the machine ensures accurate and efficient grinding. Its advanced design offers high spindle power and RPM, enabling smooth operations across different applications. The machine's compact structure and robust build make it suitable for demanding industrial environments.

The grinder is ideal for custom configurations, meeting unique production requirements. It supports a wide clamping diameter range, allowing flexibility in tool grinding. This advanced machine is perfect for industries like aerospace, automotive, and medical manufacturing that demand precision tooling solutions.

Whether you need to produce or maintain complex tools, this machine guarantees consistent and high-quality results. Its user-friendly interface simplifies operation, reducing the need for extensive training. Manufacturers can rely on this machine to improve productivity and enhance tool performance.

| SPECIFICATION | CTG-526 | CTG-536 |

| Xaxis route: | 380mm | 380mm |

| Yaxis route: | 300mm | 300mm |

| Zaxisroute: | 160mm | 160mm |

| Caxisroute: | -190~45° | -190~45° |

| Aaxis route: | 00 | 00 |

| Control motor type: | servo motor x5 axis | servo motor x5 axis |

| Spindle power: | 7.5 kw | 7.5 kw |

| Spindle maximum RPM: | 8000 | 8000 |

| Clamp diameter range: | 1~25mm | 1~36mm |

| Dimension/Weight: | 1650*1550*2000mm/1500kg | 1650*1550*2000mm/1500kg |

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 combines advanced technology with functional design for grinding tools with precision. It is a reliable choice for manufacturers seeking versatile and efficient grinding solutions.

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 is designed for industrial tool grinding with a focus on precision and efficiency. Its advanced features and versatility make it suitable for a wide range of applications. Below are its key highlights and usage scenarios:

The machine is equipped with custom software and a 3D graphical interface. This makes it user-friendly, allowing operators to visualize tool geometries and make precise adjustments. It streamlines the workflow and reduces setup time.

The advanced 5-axis CNC linkage ensures functional grinding of complex tool shapes. It is capable of producing high-precision tools and re-sharpening worn-out tools with consistency, making it ideal for industrial use.

This machine features automatic wheel dressing and tool polishing, ensuring consistent grinding quality. These functionalities enhance tool durability and reduce manual intervention, saving time and resources.

The machine is compatible with various tools, including end mills, ball-end mills, drills, taps, engraving tools, and medical instruments. Its ability to process tools made of metal and steel makes it a preferred choice for aerospace, automotive, and medical manufacturing.

The CTG-526/536 supports tool lengths up to 330mm and flute lengths of 150mm. Its wide clamping diameter range accommodates different tool sizes, ensuring flexibility in production and regrinding.

With robust construction and advanced components, the machine is designed for industrial environments. It supports high spindle RPM and reliable servo motors, ensuring smooth operations and consistent results.

The Automatic 5-Axis CNC Tool Grinding Machine CTG-526/536 combines advanced technology with custom functionality, meeting the demands of industries that require precision grinding. Its versatility and efficiency make it a valuable asset for manufacturers seeking to optimize their operations.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|