- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

ERM-12H/2OH

| Availability: | |

|---|---|

| Quantity: | |

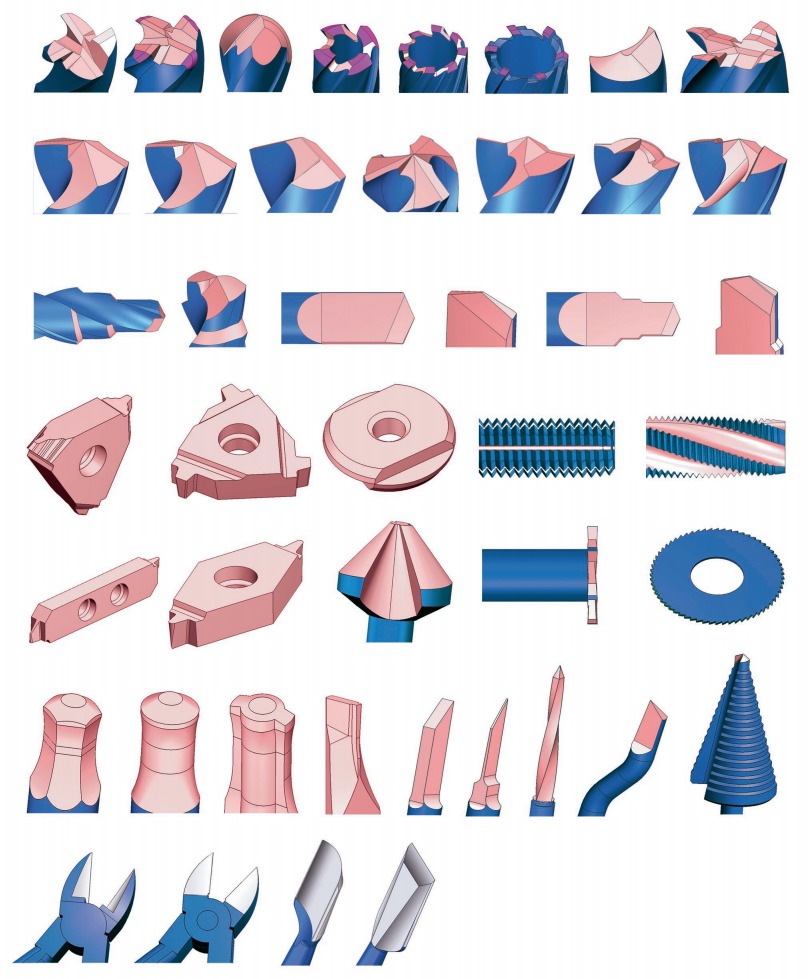

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a versatile tool designed to sharpen and maintain end mills with ease. It supports 2-flutes, 3-flutes, and 4-flutes tools, making it suitable for various machining needs. This machine ensures accurate sharpening, extending tool life and improving cutting performance in industrial and CNC environments.

With its compact design and user-friendly operation, the End Mill Re-Sharpening Machine is perfect for workshops and production lines. Adjustable axial angles allow it to handle different tool geometries, providing flexibility for diverse applications. The high-speed motor and durable grinding wheel ensure efficient and consistent sharpening for both carbide and high-speed steel tools.

This machine is widely used in industries like aerospace, automotive, and precision machining. It reduces the frequency of tool replacement, saving operational costs. Its ergonomic features and comprehensive accessory set make it a must-have for manufacturers and CNC machining centers looking to optimize tool maintenance.

| Applicable diameters | Applicable flutes | Axial angles | Grinding wheel | Power | Motor output | Rated speed | Outer dimensions | Weight | Normalaccessories | ||||||||||||||||||||

ERM-12 φ2~φ12mm ERM-12H (with fine grinding) | 2flutes、3flutes、4flutes | Secondary dearance angle6° Primary relief ange20° End gash angle30° | E12SDC (CBN Choose) | 220V±10%AC | 300W | 6000 rpm | 290x260×230(mm) | 15KG | Collet*7pcs,2 flutes holder*8pcs,3 flutesholder*8pcs, 4 flutes holder*8pcs,case*1pcs,Hexagon wrench*2pcs, controller*1pcs | ||||||||||||||||||||

| ERM-12A φ2~φ12mm | 2flutes、3flutes、4flutes | Secondary dearancea Primary relief angle22° End gash angle30° | E12SDC-A (CBN Choose) | 220V±10%AC | 300W | 6000 rpm | 290x260×230(mm) | 15KG | Collet*7pcs, 2 flutes holder*8pcs, 3 flutes holder*8pcs 4 flutes holder*8pcs, case*1pcs, Hexagon wrench*2pcs, flutes holder*1pcs controller*1pcsGaskets*6pcs, square | ||||||||||||||||||||

ERM-20 4 ~ φ 2 0 m m ERM-20H (with fine grinding) | 2Hutes、3flutes、4flutes | Secondary dearanc Primary relief angle20° End gash angle 30° | E20SDC (CBN Choose) | 220V±10%AC | 600W | 6000 rpm | 310x260×260(mm) | 22KG | Collet*8pcs,2 flutesholder*8pcs,3 flutes holder*8pcs,4 flutes holder*8pcs,case*1pcs,Hexagon,controller*1pcs wrench*2pcs | ||||||||||||||||||||

| ERM-32 φ12~φ32mm | 2flutes、3flutes、4flutes | Secondary dearancea Primaryrelef angle20° End gash angle 30° | E32SDC (CBN Choose) | 220V±10%AC | 600W | 6000 rpm | 430x350×330(mm) | 40KG | Collet*5pcs,2 flutesholder*5pcs,3 flutes holder*5pcs,4 wrench 2ps,otilerpSHexagon | ||||||||||||||||||||

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH provides an efficient and reliable solution for sharpening end mills. Its powerful features and compatibility with various tools make it the perfect choice for industrial tool maintenance. Contact us to learn more about this machine and how it can improve your operations.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a highly efficient tool designed to restore the sharpness and precision of end mills. This machine is essential for CNC machining centers and industrial operations, offering advanced capabilities for maintaining cutting tools.

This machine supports both tungsten carbide and high-speed steel tools. It delivers accurate sharpening to maintain cutting performance, serving as an ideal carbide end mill grinding machine for diverse industrial applications.

The machine provides adjustable apex angles from 90° to 150° and back angles from 0° to 12°. It allows customization based on material type, making it a reliable precision end mill grinder for achieving optimal tool sharpness.

The machine completes sharpening tasks in a short time, minimizing tool downtime. It is a preferred choice for industries requiring fast and consistent CNC tool re-sharpening equipment for high productivity.

The user-friendly design ensures that no advanced programming skills are required. Operators can use the machine effectively, making it suitable for workshops and manufacturing facilities of all sizes.

The machine is widely used in aerospace, automotive, mold-making, and precision machining. It restores end mills to their original sharpness, ensuring reliable performance for industrial tool maintenance machines in diverse sectors.

By re-sharpening end mills, this machine reduces the need for frequent replacements. It provides manufacturers with a cost-saving alternative and reliable end mill maintenance solution for long-term use.

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a practical and effective tool for maintaining cutting tools. Its advanced features, ease of operation, and versatility make it an excellent choice for machining professionals and manufacturers. Contact us to learn more about this end mill re-sharpening machine and how it can support your operations.

Q1: What is the purpose of an end mill re-sharpening machine?

A1: It restores the sharpness and geometry of end mills, improving cutting efficiency and extending tool life for industrial and CNC applications.

Q2: Can this machine sharpen both carbide and high-speed steel tools?

A2: Yes, it is designed to handle tungsten carbide and high-speed steel end mills, ensuring precise and consistent sharpening results.

Q3: How does an end mill re-sharpening machine save costs?

A3: By re-sharpening tools instead of replacing them, it reduces tool expenses and ensures long-term cost efficiency for manufacturing operations.

Q4: Is professional training required to operate this machine?

A4: No, the machine features a user-friendly design, making it easy to operate without professional programming or advanced skills.

Q5: What industries benefit most from using this machine?

A5: Industries like aerospace, automotive, mold-making, and general manufacturing rely on it for maintaining high-performance cutting tools.

Q6: Can I adjust the angles for different materials?

A6: Yes, it offers adjustable apex and back angles, allowing customization based on the material and machining requirements.

Q7: Why is this machine important for CNC machining centers?

A7: It ensures end mills are always sharp and efficient, reducing downtime and increasing productivity in CNC machining operations.

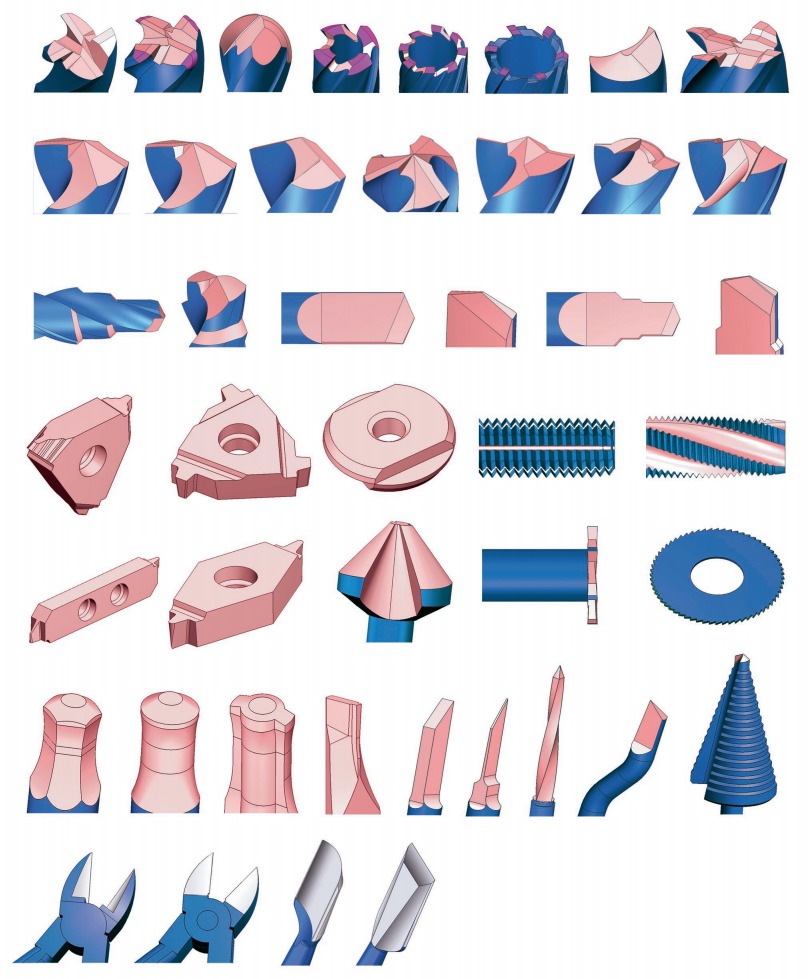

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a versatile tool designed to sharpen and maintain end mills with ease. It supports 2-flutes, 3-flutes, and 4-flutes tools, making it suitable for various machining needs. This machine ensures accurate sharpening, extending tool life and improving cutting performance in industrial and CNC environments.

With its compact design and user-friendly operation, the End Mill Re-Sharpening Machine is perfect for workshops and production lines. Adjustable axial angles allow it to handle different tool geometries, providing flexibility for diverse applications. The high-speed motor and durable grinding wheel ensure efficient and consistent sharpening for both carbide and high-speed steel tools.

This machine is widely used in industries like aerospace, automotive, and precision machining. It reduces the frequency of tool replacement, saving operational costs. Its ergonomic features and comprehensive accessory set make it a must-have for manufacturers and CNC machining centers looking to optimize tool maintenance.

| Applicable diameters | Applicable flutes | Axial angles | Grinding wheel | Power | Motor output | Rated speed | Outer dimensions | Weight | Normalaccessories | ||||||||||||||||||||

ERM-12 φ2~φ12mm ERM-12H (with fine grinding) | 2flutes、3flutes、4flutes | Secondary dearance angle6° Primary relief ange20° End gash angle30° | E12SDC (CBN Choose) | 220V±10%AC | 300W | 6000 rpm | 290x260×230(mm) | 15KG | Collet*7pcs,2 flutes holder*8pcs,3 flutesholder*8pcs, 4 flutes holder*8pcs,case*1pcs,Hexagon wrench*2pcs, controller*1pcs | ||||||||||||||||||||

| ERM-12A φ2~φ12mm | 2flutes、3flutes、4flutes | Secondary dearancea Primary relief angle22° End gash angle30° | E12SDC-A (CBN Choose) | 220V±10%AC | 300W | 6000 rpm | 290x260×230(mm) | 15KG | Collet*7pcs, 2 flutes holder*8pcs, 3 flutes holder*8pcs 4 flutes holder*8pcs, case*1pcs, Hexagon wrench*2pcs, flutes holder*1pcs controller*1pcsGaskets*6pcs, square | ||||||||||||||||||||

ERM-20 4 ~ φ 2 0 m m ERM-20H (with fine grinding) | 2Hutes、3flutes、4flutes | Secondary dearanc Primary relief angle20° End gash angle 30° | E20SDC (CBN Choose) | 220V±10%AC | 600W | 6000 rpm | 310x260×260(mm) | 22KG | Collet*8pcs,2 flutesholder*8pcs,3 flutes holder*8pcs,4 flutes holder*8pcs,case*1pcs,Hexagon,controller*1pcs wrench*2pcs | ||||||||||||||||||||

| ERM-32 φ12~φ32mm | 2flutes、3flutes、4flutes | Secondary dearancea Primaryrelef angle20° End gash angle 30° | E32SDC (CBN Choose) | 220V±10%AC | 600W | 6000 rpm | 430x350×330(mm) | 40KG | Collet*5pcs,2 flutesholder*5pcs,3 flutes holder*5pcs,4 wrench 2ps,otilerpSHexagon | ||||||||||||||||||||

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH provides an efficient and reliable solution for sharpening end mills. Its powerful features and compatibility with various tools make it the perfect choice for industrial tool maintenance. Contact us to learn more about this machine and how it can improve your operations.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a highly efficient tool designed to restore the sharpness and precision of end mills. This machine is essential for CNC machining centers and industrial operations, offering advanced capabilities for maintaining cutting tools.

This machine supports both tungsten carbide and high-speed steel tools. It delivers accurate sharpening to maintain cutting performance, serving as an ideal carbide end mill grinding machine for diverse industrial applications.

The machine provides adjustable apex angles from 90° to 150° and back angles from 0° to 12°. It allows customization based on material type, making it a reliable precision end mill grinder for achieving optimal tool sharpness.

The machine completes sharpening tasks in a short time, minimizing tool downtime. It is a preferred choice for industries requiring fast and consistent CNC tool re-sharpening equipment for high productivity.

The user-friendly design ensures that no advanced programming skills are required. Operators can use the machine effectively, making it suitable for workshops and manufacturing facilities of all sizes.

The machine is widely used in aerospace, automotive, mold-making, and precision machining. It restores end mills to their original sharpness, ensuring reliable performance for industrial tool maintenance machines in diverse sectors.

By re-sharpening end mills, this machine reduces the need for frequent replacements. It provides manufacturers with a cost-saving alternative and reliable end mill maintenance solution for long-term use.

The Precision End Mill Re-Sharpening Machine ERM-12H/2OH is a practical and effective tool for maintaining cutting tools. Its advanced features, ease of operation, and versatility make it an excellent choice for machining professionals and manufacturers. Contact us to learn more about this end mill re-sharpening machine and how it can support your operations.

Q1: What is the purpose of an end mill re-sharpening machine?

A1: It restores the sharpness and geometry of end mills, improving cutting efficiency and extending tool life for industrial and CNC applications.

Q2: Can this machine sharpen both carbide and high-speed steel tools?

A2: Yes, it is designed to handle tungsten carbide and high-speed steel end mills, ensuring precise and consistent sharpening results.

Q3: How does an end mill re-sharpening machine save costs?

A3: By re-sharpening tools instead of replacing them, it reduces tool expenses and ensures long-term cost efficiency for manufacturing operations.

Q4: Is professional training required to operate this machine?

A4: No, the machine features a user-friendly design, making it easy to operate without professional programming or advanced skills.

Q5: What industries benefit most from using this machine?

A5: Industries like aerospace, automotive, mold-making, and general manufacturing rely on it for maintaining high-performance cutting tools.

Q6: Can I adjust the angles for different materials?

A6: Yes, it offers adjustable apex and back angles, allowing customization based on the material and machining requirements.

Q7: Why is this machine important for CNC machining centers?

A7: It ensures end mills are always sharp and efficient, reducing downtime and increasing productivity in CNC machining operations.