- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S is a precision tool designed for restoring end mills efficiently. Built with a sturdy structure, it supports end mill diameters ranging from 3 mm to 20 mm. This machine ensures high-quality grinding results, reducing production downtime and improving tool lifespan.

The ERM-12S model is compact and lightweight, making it ideal for smaller tool maintenance tasks. Its high-precision grinding wheel and advanced control system allow accurate sharpening for 2-flute, 3-flute, and 4-flute end mills. The ERM-20S model offers higher power for handling larger tools, making it suitable for industrial-scale operations.

This CNC tool sharpening equipment is designed to meet diverse industry needs, from aerospace to automotive and general metalworking. Its automatic operation simplifies the tool maintenance process, eliminating the need for specialized grinding skills.

Both models are equipped with user-friendly interfaces and come with essential accessories, including collets, tool holders, and hex wrenches. The machine's compact design and portability ensure efficient workspace utilization. With consistent results and advanced grinding features, the ERM-12S/20S is a reliable solution for tool grinding.

| Model | ERM-12S | ERM-20S | |||||||||||||||||||||||

| Applicablediameters: | φ3~φ12mm | 4~φ20mm | |||||||||||||||||||||||

| Applicable flutes: | 2flutes、3flutes、4flutes | ||||||||||||||||||||||||

| Axial angles: | Secondary dearance angle 6° | End gash angle 30° | |||||||||||||||||||||||

| Grinding wheel: | E12SDC (CBN Choose) | E20SDC (CBN Choose) | |||||||||||||||||||||||

| Motor output: | 220V/300W | 220V/600W | |||||||||||||||||||||||

| Weight: | 13KG | 16KG | |||||||||||||||||||||||

| Normalaccessories: | Collet*7pcs, 2 flutes holder*3 pcs, 3 flutes holder*3pcs, 4 flutes holder*3pcs, case*1pcs, Hexagon wrench*2pcs, controller*1pcs | Collet*8pcs,2 flutes holder*3pcs, 3 flutes holder*3pcs, 4 flutes holder*3pcs, case*1pcs, Hexagon wrench*2pcs, controller*1pcs | |||||||||||||||||||||||

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

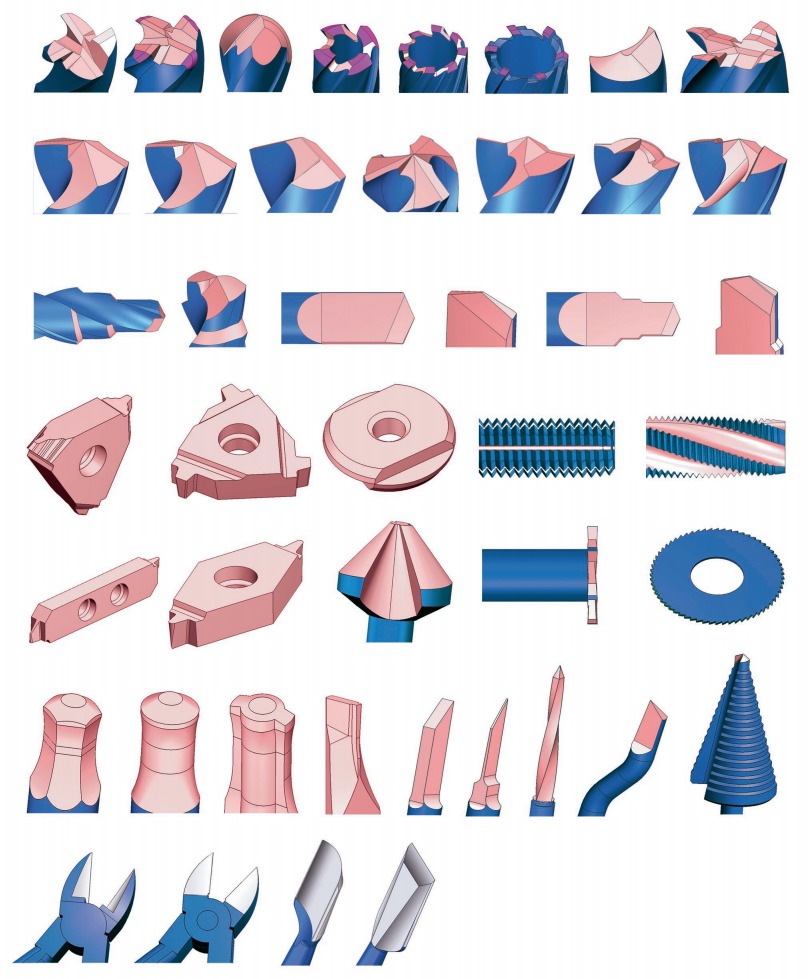

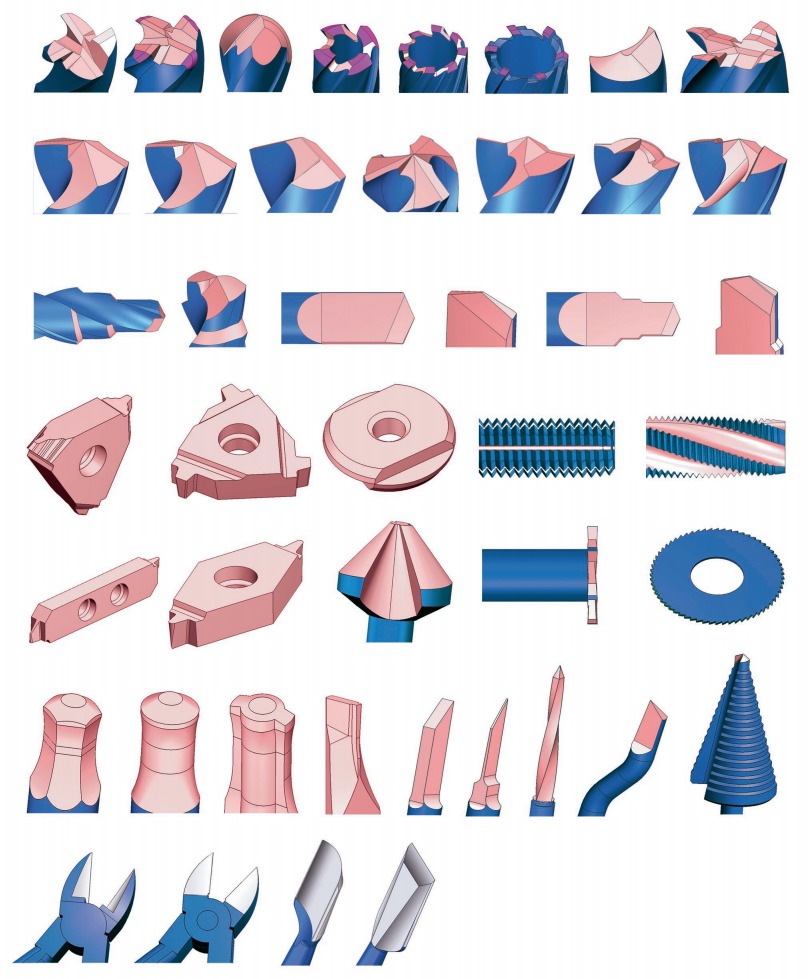

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S supports a wide range of tools, including 2-flute, 3-flute, and 4-flute end mills. It is compatible with both tungsten carbide and high-speed steel materials, making it suitable for various industrial applications.

This machine ensures accurate grinding of helix angles, cutting edges, and front cutting angles. Precision sharpening enhances the cutting efficiency and extends the lifespan of end mills, making it ideal for high-precision machining tasks.

The ERM-12S/20S is designed for quick and easy operation. It allows users to complete the sharpening process in under one minute, without requiring advanced technical skills. This feature increases productivity and reduces downtime.

Users can adjust the tool's cutting angles based on the material being processed. This customizability ensures that the end mills deliver optimal performance for a variety of machining needs, from metal cutting to steel shaping.

The machine’s compact structure makes it a practical choice for workshops and industrial facilities with limited space. Its lightweight design also allows for easy portability, without compromising on performance.

CNC Machining: Suitable for maintaining end mills used in CNC machines for precision cutting.

Metalworking: Ideal for reshaping and sharpening tools used in metal and steel processing.

Aerospace: Ensures high-precision tools for manufacturing aircraft components.

Automotive: Supports tool maintenance for engine and transmission manufacturing.

Medical Equipment: Delivers accurate sharpening for tools used in surgical equipment production.

Mold and Die Making: Enhances the efficiency of tools used in intricate mold fabrication.

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S combines advanced features with practical usability. As a trusted end mill re-sharpening machine supplier, it ensures consistent and precise tool maintenance for various industries.

Q1. Can the End Mill Re-Sharpening Machine handle different flute designs?

A1. Yes, it works with various flute designs, including 2-flute, 3-flute, and 4-flute end mills.

Q2. What materials are compatible with this re-sharpening machine?

A2. It is designed for sharpening tungsten carbide and high-speed steel end mills.

Q3. How does this machine ensure precise sharpening?

A3. The machine uses advanced grinding wheels and precise adjustments to ensure accurate and consistent sharpening results.

Q4. Is the machine easy to operate for beginners?

A4. Yes, it features a user-friendly design that allows beginners to sharpen tools efficiently without specialized skills.

Q5. Can this machine reduce production downtime?

A5. Yes, its quick sharpening process and automatic functions help minimize downtime during tool maintenance.

Q6. Is the End Mill Re-Sharpening Machine suitable for small workshops?

A6. Its compact structure and lightweight build make it ideal for small spaces and portable use.

Q7. How does this machine benefit CNC machining operations?

A7. It maintains sharpness for end mills, improving cutting precision and efficiency in CNC machining tasks.

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S is a precision tool designed for restoring end mills efficiently. Built with a sturdy structure, it supports end mill diameters ranging from 3 mm to 20 mm. This machine ensures high-quality grinding results, reducing production downtime and improving tool lifespan.

The ERM-12S model is compact and lightweight, making it ideal for smaller tool maintenance tasks. Its high-precision grinding wheel and advanced control system allow accurate sharpening for 2-flute, 3-flute, and 4-flute end mills. The ERM-20S model offers higher power for handling larger tools, making it suitable for industrial-scale operations.

This CNC tool sharpening equipment is designed to meet diverse industry needs, from aerospace to automotive and general metalworking. Its automatic operation simplifies the tool maintenance process, eliminating the need for specialized grinding skills.

Both models are equipped with user-friendly interfaces and come with essential accessories, including collets, tool holders, and hex wrenches. The machine's compact design and portability ensure efficient workspace utilization. With consistent results and advanced grinding features, the ERM-12S/20S is a reliable solution for tool grinding.

| Model | ERM-12S | ERM-20S | |||||||||||||||||||||||

| Applicablediameters: | φ3~φ12mm | 4~φ20mm | |||||||||||||||||||||||

| Applicable flutes: | 2flutes、3flutes、4flutes | ||||||||||||||||||||||||

| Axial angles: | Secondary dearance angle 6° | End gash angle 30° | |||||||||||||||||||||||

| Grinding wheel: | E12SDC (CBN Choose) | E20SDC (CBN Choose) | |||||||||||||||||||||||

| Motor output: | 220V/300W | 220V/600W | |||||||||||||||||||||||

| Weight: | 13KG | 16KG | |||||||||||||||||||||||

| Normalaccessories: | Collet*7pcs, 2 flutes holder*3 pcs, 3 flutes holder*3pcs, 4 flutes holder*3pcs, case*1pcs, Hexagon wrench*2pcs, controller*1pcs | Collet*8pcs,2 flutes holder*3pcs, 3 flutes holder*3pcs, 4 flutes holder*3pcs, case*1pcs, Hexagon wrench*2pcs, controller*1pcs | |||||||||||||||||||||||

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S supports a wide range of tools, including 2-flute, 3-flute, and 4-flute end mills. It is compatible with both tungsten carbide and high-speed steel materials, making it suitable for various industrial applications.

This machine ensures accurate grinding of helix angles, cutting edges, and front cutting angles. Precision sharpening enhances the cutting efficiency and extends the lifespan of end mills, making it ideal for high-precision machining tasks.

The ERM-12S/20S is designed for quick and easy operation. It allows users to complete the sharpening process in under one minute, without requiring advanced technical skills. This feature increases productivity and reduces downtime.

Users can adjust the tool's cutting angles based on the material being processed. This customizability ensures that the end mills deliver optimal performance for a variety of machining needs, from metal cutting to steel shaping.

The machine’s compact structure makes it a practical choice for workshops and industrial facilities with limited space. Its lightweight design also allows for easy portability, without compromising on performance.

CNC Machining: Suitable for maintaining end mills used in CNC machines for precision cutting.

Metalworking: Ideal for reshaping and sharpening tools used in metal and steel processing.

Aerospace: Ensures high-precision tools for manufacturing aircraft components.

Automotive: Supports tool maintenance for engine and transmission manufacturing.

Medical Equipment: Delivers accurate sharpening for tools used in surgical equipment production.

Mold and Die Making: Enhances the efficiency of tools used in intricate mold fabrication.

The Automatic End Mill Re-Sharpening Machine ERM-12S/20S combines advanced features with practical usability. As a trusted end mill re-sharpening machine supplier, it ensures consistent and precise tool maintenance for various industries.

Q1. Can the End Mill Re-Sharpening Machine handle different flute designs?

A1. Yes, it works with various flute designs, including 2-flute, 3-flute, and 4-flute end mills.

Q2. What materials are compatible with this re-sharpening machine?

A2. It is designed for sharpening tungsten carbide and high-speed steel end mills.

Q3. How does this machine ensure precise sharpening?

A3. The machine uses advanced grinding wheels and precise adjustments to ensure accurate and consistent sharpening results.

Q4. Is the machine easy to operate for beginners?

A4. Yes, it features a user-friendly design that allows beginners to sharpen tools efficiently without specialized skills.

Q5. Can this machine reduce production downtime?

A5. Yes, its quick sharpening process and automatic functions help minimize downtime during tool maintenance.

Q6. Is the End Mill Re-Sharpening Machine suitable for small workshops?

A6. Its compact structure and lightweight build make it ideal for small spaces and portable use.

Q7. How does this machine benefit CNC machining operations?

A7. It maintains sharpness for end mills, improving cutting precision and efficiency in CNC machining tasks.