- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The CNC Gun Drill Grinding Machine GD-5A is specifically developed for deep hole drilling tool sharpening and maintenance. It provides industrial-level performance, ensuring precision and efficiency in metalworking applications. Designed for professional manufacturers, it supports high-quality tool maintenance, prolonging the lifespan of gun drills and enhancing production output.

This grinding equipment is equipped with an advanced CNC control system, allowing accurate adjustments for sharpening tools used in deep hole drilling. Its high-speed spindle reaches up to 8000 RPM, ensuring efficient grinding for metal tools with consistent performance. The machine is also fitted with a coolant filter, which keeps grinding operations smooth and minimizes tool wear.

The GD-5A supports a variety of tool sizes and blade geometries, making it a versatile grinder for industrial needs. Its durable construction ensures long-term reliability, even under continuous operation in demanding environments. Ideal for metalworking industries such as aerospace, automotive, and mold-making, this machine provides a professional-grade solution for tool sharpening and maintenance.

Designed with user-friendly features, the GD-5A reduces operator fatigue while delivering precise and efficient grinding results. Its customizable configurations make it adaptable for different tool designs, enhancing production flexibility. This grinder is a valuable choice for manufacturers seeking quality grinding equipment that meets industrial standards.

| SPECIFICATION | GD-5A |

| Xaxis route: | 240mm |

| Yaxis route: | 315mm |

| Zaxis route: | 185mm |

| Caxis route: | -5~95° |

| A axis route: | |

| Control motor type: | servo motor x5 axis |

| Spindle power: | 7.5 kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1810*1340*2020mm/2400kg |

The CNC Gun Drill Grinding Machine GD-5A combines precision, durability, and efficiency, making it the ideal choice for professional tool maintenance and industrial grinding applications.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Durable CNC Gun Drill Grinding Machine GD-5A is engineered for precision and efficiency in industrial tool grinding. Designed for professional manufacturers, it ensures high-quality sharpening and maintenance for deep hole drilling tools. Below are its key features and applications:

This machine uses a 5-axis CNC system to deliver precise adjustments for grinding gun drills. It ensures accurate sharpening of drill heads and V-flutes, optimizing quality for metalworking applications.

The GD-5A supports one-clamp operation for grinding blades and flutes, saving time and simplifying tool maintenance. Its integrated coolant filter reduces heat and prolongs tool life, ensuring consistent performance.

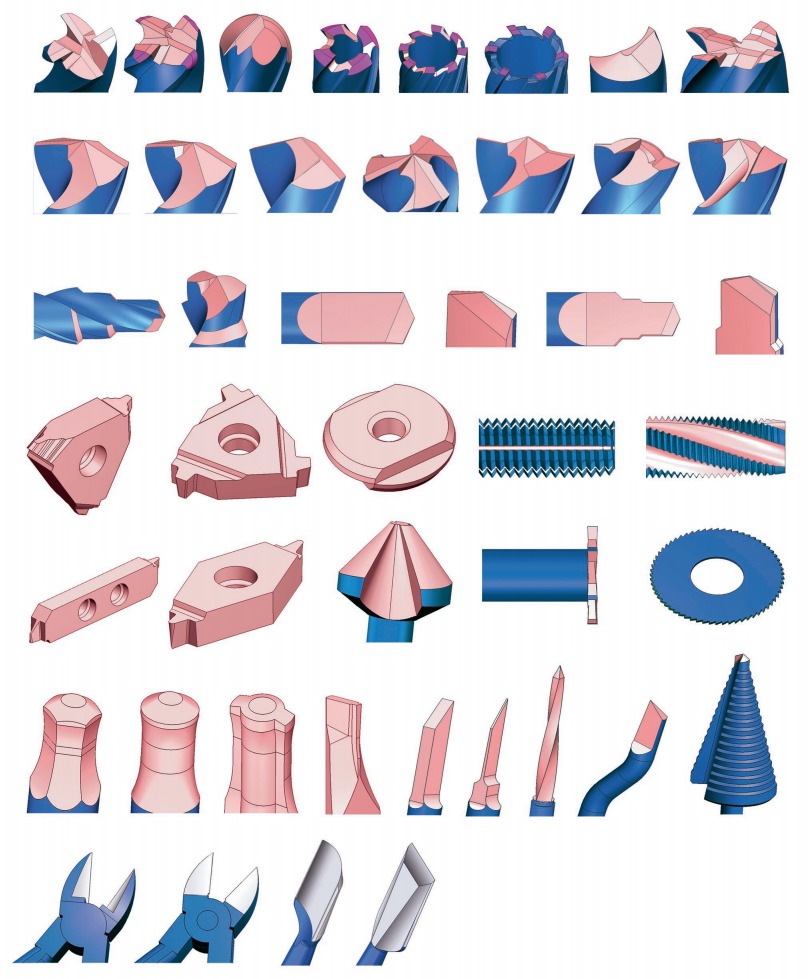

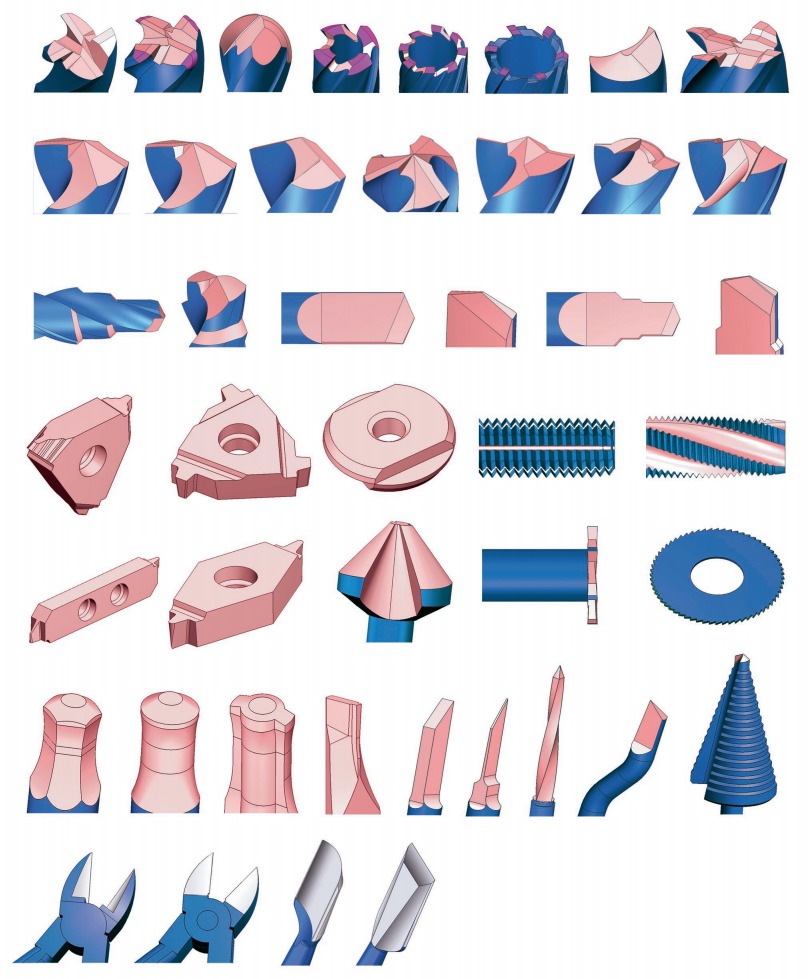

The grinder is compatible with standard gun drills, ball-end gun drills, flat-end gun drills, tapered drills, and dual-flute drill tips. This versatility makes it suitable for various industrial applications, including deep hole drilling.

Built with heavy-duty components, the GD-5A is designed for continuous operation in demanding industrial environments. Its durable structure ensures long-term reliability, making it an ideal choice for metalworking and manufacturing.

The GD-5A is widely used in industries such as aerospace, automotive, and mold-making. It delivers high precision for deep hole drilling tools, meeting the needs of manufacturers focused on quality and efficiency.

The machine features a 3D graphical interface for easy operation, making it accessible to operators with varying experience levels. Its compact structure allows seamless integration into production lines, optimizing space usage.

The Durable CNC Gun Drill Grinding Machine GD-5A combines advanced technology with durable construction, ensuring precision, efficiency, and reliability for industrial tool grinding and sharpening tasks. Its versatility and quality make it a valuable asset for professional manufacturers.

Q1: What types of drills can the CNC Gun Drill Grinding Machine handle?

A1: It can grind standard gun drills, ball-end drills, flat-end drills, tapered drills, and dual-flute drill tips.

Q2: How does the CNC Gun Drill Grinding Machine improve tool precision?

A2: The machine uses a 5-axis CNC control system, ensuring precise sharpening for deep hole drilling tools.

Q3: Is the CNC Gun Drill Grinding Machine suitable for industrial use?

A3: Yes, it is designed for industrial metalworking and supports continuous operation in demanding environments.

Q4: Can I customize the CNC Gun Drill Grinding Machine for specific production needs?

A4: Yes, the machine offers customizable configurations for different tool sizes and geometries.

Q5: What industries commonly use the CNC Gun Drill Grinding Machine?

A5: It is widely used in aerospace, automotive, mold-making, and other industries requiring precision tool grinding.

Q6: Does the CNC Gun Drill Grinding Machine include a coolant system?

A6: Yes, it features an integrated coolant filter to reduce heat and maintain blade quality during grinding.

Q7: Is the CNC Gun Drill Grinding Machine easy for operators to use?

A7: Yes, it includes a user-friendly 3D graphical interface, simplifying operation for operators at any skill level.

The CNC Gun Drill Grinding Machine GD-5A is specifically developed for deep hole drilling tool sharpening and maintenance. It provides industrial-level performance, ensuring precision and efficiency in metalworking applications. Designed for professional manufacturers, it supports high-quality tool maintenance, prolonging the lifespan of gun drills and enhancing production output.

This grinding equipment is equipped with an advanced CNC control system, allowing accurate adjustments for sharpening tools used in deep hole drilling. Its high-speed spindle reaches up to 8000 RPM, ensuring efficient grinding for metal tools with consistent performance. The machine is also fitted with a coolant filter, which keeps grinding operations smooth and minimizes tool wear.

The GD-5A supports a variety of tool sizes and blade geometries, making it a versatile grinder for industrial needs. Its durable construction ensures long-term reliability, even under continuous operation in demanding environments. Ideal for metalworking industries such as aerospace, automotive, and mold-making, this machine provides a professional-grade solution for tool sharpening and maintenance.

Designed with user-friendly features, the GD-5A reduces operator fatigue while delivering precise and efficient grinding results. Its customizable configurations make it adaptable for different tool designs, enhancing production flexibility. This grinder is a valuable choice for manufacturers seeking quality grinding equipment that meets industrial standards.

| SPECIFICATION | GD-5A |

| Xaxis route: | 240mm |

| Yaxis route: | 315mm |

| Zaxis route: | 185mm |

| Caxis route: | -5~95° |

| A axis route: | |

| Control motor type: | servo motor x5 axis |

| Spindle power: | 7.5 kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1810*1340*2020mm/2400kg |

The CNC Gun Drill Grinding Machine GD-5A combines precision, durability, and efficiency, making it the ideal choice for professional tool maintenance and industrial grinding applications.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Durable CNC Gun Drill Grinding Machine GD-5A is engineered for precision and efficiency in industrial tool grinding. Designed for professional manufacturers, it ensures high-quality sharpening and maintenance for deep hole drilling tools. Below are its key features and applications:

This machine uses a 5-axis CNC system to deliver precise adjustments for grinding gun drills. It ensures accurate sharpening of drill heads and V-flutes, optimizing quality for metalworking applications.

The GD-5A supports one-clamp operation for grinding blades and flutes, saving time and simplifying tool maintenance. Its integrated coolant filter reduces heat and prolongs tool life, ensuring consistent performance.

The grinder is compatible with standard gun drills, ball-end gun drills, flat-end gun drills, tapered drills, and dual-flute drill tips. This versatility makes it suitable for various industrial applications, including deep hole drilling.

Built with heavy-duty components, the GD-5A is designed for continuous operation in demanding industrial environments. Its durable structure ensures long-term reliability, making it an ideal choice for metalworking and manufacturing.

The GD-5A is widely used in industries such as aerospace, automotive, and mold-making. It delivers high precision for deep hole drilling tools, meeting the needs of manufacturers focused on quality and efficiency.

The machine features a 3D graphical interface for easy operation, making it accessible to operators with varying experience levels. Its compact structure allows seamless integration into production lines, optimizing space usage.

The Durable CNC Gun Drill Grinding Machine GD-5A combines advanced technology with durable construction, ensuring precision, efficiency, and reliability for industrial tool grinding and sharpening tasks. Its versatility and quality make it a valuable asset for professional manufacturers.

Q1: What types of drills can the CNC Gun Drill Grinding Machine handle?

A1: It can grind standard gun drills, ball-end drills, flat-end drills, tapered drills, and dual-flute drill tips.

Q2: How does the CNC Gun Drill Grinding Machine improve tool precision?

A2: The machine uses a 5-axis CNC control system, ensuring precise sharpening for deep hole drilling tools.

Q3: Is the CNC Gun Drill Grinding Machine suitable for industrial use?

A3: Yes, it is designed for industrial metalworking and supports continuous operation in demanding environments.

Q4: Can I customize the CNC Gun Drill Grinding Machine for specific production needs?

A4: Yes, the machine offers customizable configurations for different tool sizes and geometries.

Q5: What industries commonly use the CNC Gun Drill Grinding Machine?

A5: It is widely used in aerospace, automotive, mold-making, and other industries requiring precision tool grinding.

Q6: Does the CNC Gun Drill Grinding Machine include a coolant system?

A6: Yes, it features an integrated coolant filter to reduce heat and maintain blade quality during grinding.

Q7: Is the CNC Gun Drill Grinding Machine easy for operators to use?

A7: Yes, it includes a user-friendly 3D graphical interface, simplifying operation for operators at any skill level.