- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The CNC Gun Drill Grinding Machine GD-3AC is designed for precision sharpening and maintenance of deep hole drilling tools. Developed by Liyou, it is part of the CNC Gun Drill Grinding Machine Series, tailored for professional tool maintenance and metalworking industries.

This industrial equipment features a three-axis servo motor system, ensuring accurate grinding for various tool geometries. Its high-speed spindle delivers consistent performance, while the integrated coolant filter prevents overheating, extending the lifespan of blades during sharpening. This grinder is an efficient and reliable choice for deep hole drilling applications.

Compact yet powerful, the GD-3AC is ideal for industrial environments with limited space. It offers customizable capabilities, allowing compatibility with standard, ball-end, and flat-end gun drills. The durable construction ensures the machine performs well under heavy-duty usage, meeting the demands of professional manufacturers.

The GD-3AC is widely used in industries such as aerospace, automotive, and mold-making, where precision and quality are vital. Its efficient design and advanced features make it a trusted tool for maintaining and sharpening blades for metalworking applications.

| SPECIFICATION | GD-3AC |

| Xaxis route: | 445mm |

| Yaxis route: | 198mm |

| Zaxis route: | 90mm |

| Control motor type: | servo motor x3 axis |

| Spindle power: | 7.5 kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1580*1280*1900mm/1880kg |

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The CNC Gun Drill Grinding Machine GD-3AC offers an efficient solution for sharpening and maintaining deep hole drilling tools. Its design focuses on precision and durability, making it suitable for professional use in metalworking industries.

The GD-3AC uses advanced three-axis CNC control to ensure precise sharpening of gun drills. This system provides optimal accuracy, crucial for deep hole drilling applications.

You can process multiple gun drill heads or shanks at the same time, improving workflow efficiency. This capability reduces downtime and increases production output for industrial operations.

An integrated coolant filter minimizes heat during grinding, which helps to protect tool blades. This feature improves blade lifespan and ensures consistent tool quality for metalwork.

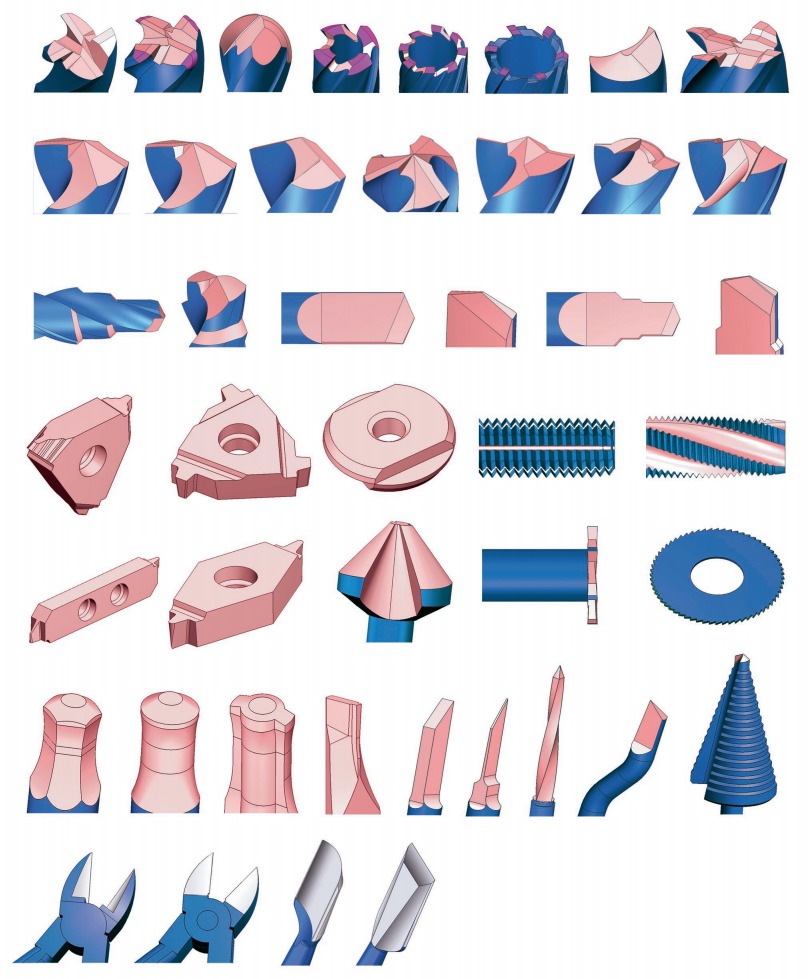

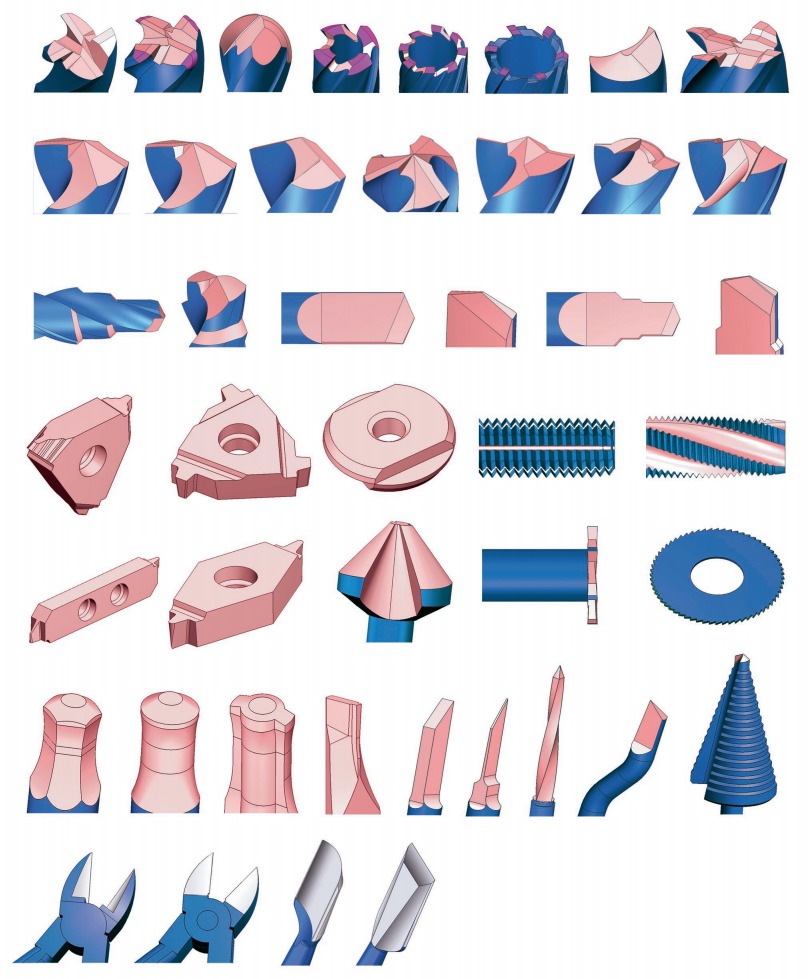

The machine handles a wide range of tool geometries, including flat-end, ball-end, and tapered gun drills. This flexibility makes it adaptable to various production needs, from aerospace to automotive applications.

The durable construction of the GD-3AC supports continuous use in heavy-duty industrial environments. Its compact size allows easy integration into production lines without taking up excessive space.

This grinder is ideal for industries requiring precision and efficiency. Manufacturers in aerospace, automotive, and mold-making rely on it for maintaining high-quality tools for deep hole drilling and other metalworking tasks.

The CNC Gun Drill Grinding Machine GD-3AC for Metal is a professional-grade solution designed for industrial use. Its precision, efficiency, and robust design make it an essential piece of equipment for maintaining tools and achieving consistent results in metalworking.

Q1: What types of tools can the CNC Gun Drill Grinding Machine GD-3AC sharpen?

A1: It can sharpen various gun drills, including flat-end, ball-end, and tapered tools used for deep hole drilling.

Q2: How does this machine improve tool maintenance for metalworking?

A2: It ensures precise sharpening, extending blade lifespan and maintaining high tool quality for efficient metalworking operations.

Q3: Is the CNC Gun Drill Grinding Machine suitable for professional manufacturers?

A3: Yes, it is designed for industrial applications, offering reliable performance for aerospace, automotive, and mold-making industries.

Q4: Does this machine help reduce production costs?

A4: By sharpening multiple tools simultaneously and requiring no specialized operators, it reduces labor and downtime expenses.

Q5: How does the integrated coolant filter enhance performance?

A5: The coolant filter efficiently manages heat during grinding, protecting blades and ensuring consistent sharpening results.

Q6: Is the CNC Gun Drill Grinding Machine easy to integrate into existing production lines?

A6: Yes, its compact and durable design allows seamless integration into various industrial workflows.

Q7: What makes this machine reliable for heavy-duty use?

A7: Its robust construction and advanced CNC control ensure durability and precision during continuous industrial operations.

The CNC Gun Drill Grinding Machine GD-3AC is designed for precision sharpening and maintenance of deep hole drilling tools. Developed by Liyou, it is part of the CNC Gun Drill Grinding Machine Series, tailored for professional tool maintenance and metalworking industries.

This industrial equipment features a three-axis servo motor system, ensuring accurate grinding for various tool geometries. Its high-speed spindle delivers consistent performance, while the integrated coolant filter prevents overheating, extending the lifespan of blades during sharpening. This grinder is an efficient and reliable choice for deep hole drilling applications.

Compact yet powerful, the GD-3AC is ideal for industrial environments with limited space. It offers customizable capabilities, allowing compatibility with standard, ball-end, and flat-end gun drills. The durable construction ensures the machine performs well under heavy-duty usage, meeting the demands of professional manufacturers.

The GD-3AC is widely used in industries such as aerospace, automotive, and mold-making, where precision and quality are vital. Its efficient design and advanced features make it a trusted tool for maintaining and sharpening blades for metalworking applications.

| SPECIFICATION | GD-3AC |

| Xaxis route: | 445mm |

| Yaxis route: | 198mm |

| Zaxis route: | 90mm |

| Control motor type: | servo motor x3 axis |

| Spindle power: | 7.5 kw |

| Spindle maximum RPM: | 8000 |

| Dimension/Weight: | 1580*1280*1900mm/1880kg |

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The CNC Gun Drill Grinding Machine GD-3AC offers an efficient solution for sharpening and maintaining deep hole drilling tools. Its design focuses on precision and durability, making it suitable for professional use in metalworking industries.

The GD-3AC uses advanced three-axis CNC control to ensure precise sharpening of gun drills. This system provides optimal accuracy, crucial for deep hole drilling applications.

You can process multiple gun drill heads or shanks at the same time, improving workflow efficiency. This capability reduces downtime and increases production output for industrial operations.

An integrated coolant filter minimizes heat during grinding, which helps to protect tool blades. This feature improves blade lifespan and ensures consistent tool quality for metalwork.

The machine handles a wide range of tool geometries, including flat-end, ball-end, and tapered gun drills. This flexibility makes it adaptable to various production needs, from aerospace to automotive applications.

The durable construction of the GD-3AC supports continuous use in heavy-duty industrial environments. Its compact size allows easy integration into production lines without taking up excessive space.

This grinder is ideal for industries requiring precision and efficiency. Manufacturers in aerospace, automotive, and mold-making rely on it for maintaining high-quality tools for deep hole drilling and other metalworking tasks.

The CNC Gun Drill Grinding Machine GD-3AC for Metal is a professional-grade solution designed for industrial use. Its precision, efficiency, and robust design make it an essential piece of equipment for maintaining tools and achieving consistent results in metalworking.

Q1: What types of tools can the CNC Gun Drill Grinding Machine GD-3AC sharpen?

A1: It can sharpen various gun drills, including flat-end, ball-end, and tapered tools used for deep hole drilling.

Q2: How does this machine improve tool maintenance for metalworking?

A2: It ensures precise sharpening, extending blade lifespan and maintaining high tool quality for efficient metalworking operations.

Q3: Is the CNC Gun Drill Grinding Machine suitable for professional manufacturers?

A3: Yes, it is designed for industrial applications, offering reliable performance for aerospace, automotive, and mold-making industries.

Q4: Does this machine help reduce production costs?

A4: By sharpening multiple tools simultaneously and requiring no specialized operators, it reduces labor and downtime expenses.

Q5: How does the integrated coolant filter enhance performance?

A5: The coolant filter efficiently manages heat during grinding, protecting blades and ensuring consistent sharpening results.

Q6: Is the CNC Gun Drill Grinding Machine easy to integrate into existing production lines?

A6: Yes, its compact and durable design allows seamless integration into various industrial workflows.

Q7: What makes this machine reliable for heavy-duty use?

A7: Its robust construction and advanced CNC control ensure durability and precision during continuous industrial operations.