- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are designed to restore the sharpness and cutting efficiency of drill bits. These machines cater to industries that require high precision and cost-effective grinding solutions. They are suitable for sharpening high-speed steel and tungsten steel drills, ensuring consistent performance and extended tool life.

Both models feature a space-saving design, making them ideal for workshops and manufacturing facilities with limited space. Their lightweight structure allows for easy transportation and setup while maintaining stability during operation. These machines are engineered to fit seamlessly into industrial environments.

The DRM-13 and DRM-20 are equipped with advanced grinding wheels (D13CBN and D20CBN), optimized for accurate and efficient sharpening. The grinding scope for apex angles ranges from 90° to 150°, enabling precise sharpening for a variety of drill types. With a rated speed of 5000 rpm, these machines deliver consistent results with every use.

The DRM-13 supports drill diameters of 3mm to 13mm, while the DRM-20 accommodates larger drills ranging from 3mm to 20mm. This versatility makes them suitable for various industrial applications, from small-scale operations to large-scale manufacturing.

These machines provide an affordable solution for maintaining your tools. By re-sharpening drills instead of replacing them, businesses can significantly reduce operational costs while ensuring tools remain sharp and reliable for extended periods.

| MODEL | Applicable diameter ot the drll | Grinaing scope ot the apex angle | Grinding scope ot the dorsal nom | Grnding wheel | Length of drill | Power | Motor output | Raded speed | Outer dimensions | weight | Normalaccessories | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-13 | φ3~φ13mm | 90°~150° | 0°~12° | D13CBN (SDC Choose) | —— | 220V±10%AC | 250W | 5000 rpm | 290x260x230(mm) | 16KG | Collet φ3~φ13mm(11pcs),Hexagon wrench*2pcs, Chuck group*1 Group,controller*1pcs | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-20 | 中3~φ20mm | 90°~150° | 0°~12° | D20CBN (SDC Choose) | —— | 220V±10%AC | 250W | 5000 pm | 345x160x210(mm) | 19KG | Collet φ3~φ20mm(18pcs),Hexagon wrench*2pcs, Chuck group*2 Group,controller*1pcs | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-50 | Taper-shank drillφ13~φ50mm | 118°~180° | 4° | D50CBN | Maximum length 400mm | AC220V | 200W | 2800 rpm | 650*590*350(mm) | 68KG | Jacket for taper shank(4-1#,4-2#,4-3#)one for each, lron wedge block*2pcs,Hexagon wrench*2pcS Chuck group*1Group | ||||||||||||||||||||||||||||||||||||||||||||||||

Grinding wheel: SDC wheels used for tung-sten carbide tools, CBN wheels used for high-speed steel tools.

These Drill Re-Sharpening Machines are a reliable choice for industries looking for efficient and affordable drill re-sharpening solutions. Contact us today to learn how the Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) can meet your tool maintenance needs.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are designed to restore the precision and cutting efficiency of drill bits. These machines are suitable for a variety of industries requiring reliable performance and cost-effective solutions. Below are the key features and applications of these advanced grinding machines.

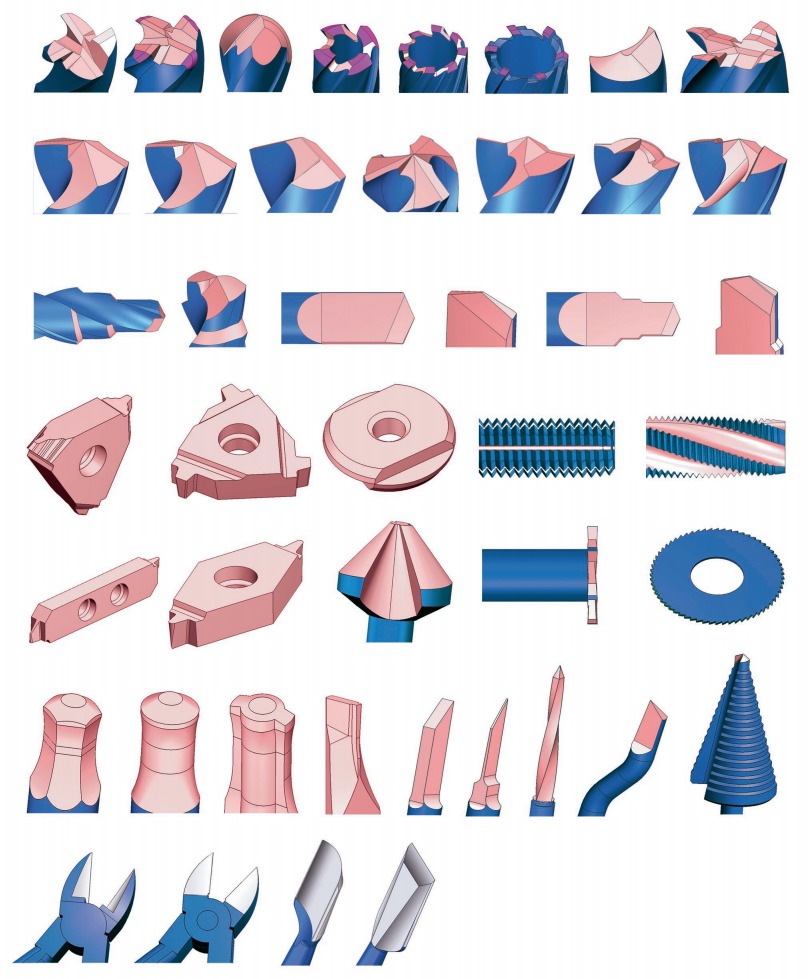

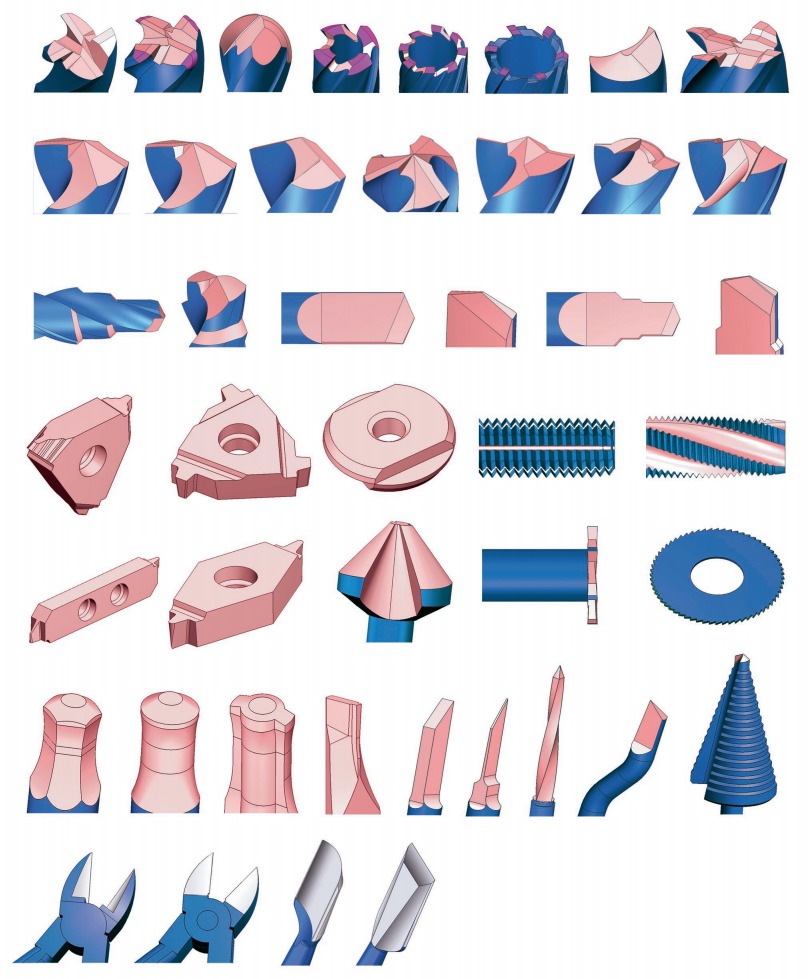

The machines are specifically designed to sharpen high-speed steel and tungsten steel drill bits. This compatibility ensures precise and efficient grinding, making them ideal for various industrial applications. Whether you’re dealing with tough materials or standard drill bits, these machines deliver consistent results.

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) offer adjustable apex angles ranging from 90° to 150° and back angles from 0° to 12°. These customizable settings enable precise sharpening for different materials and applications, ensuring optimal tool performance.

Both machines are designed for quick and easy operation, allowing users to complete sharpening tasks in just one minute. Their intuitive design eliminates the need for professional tool grinders or programming skills, making them accessible for operators of all experience levels.

The DRM-13 supports drill diameters from 3mm to 13mm, while the DRM-20 accommodates up to 20mm. This wide range of compatibility makes these machines suitable for small to medium-sized drill bits, catering to diverse industrial requirements. The machines also allow for sharpening drills of unlimited lengths, increasing their usability.

These drill re-sharpening machines are widely used in industries such as automotive, aerospace, mold-making, and general manufacturing. Their precision grinding capabilities make them ideal for maintaining drills used in critical applications. By keeping tools sharp and efficient, they help improve productivity and reduce downtime.

By restoring the cutting edge of drills, these machines significantly reduce the need for frequent tool replacements. Their affordable price and ability to be operated by a single person make them a cost-effective solution for businesses aiming to save on operational expenses.

With their combination of advanced features, versatile applications, and ease of use, the Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are the perfect choice for industries looking for precision drill grinding equipment. Contact us today to learn more about these affordable drill re-sharpening machines and how they can benefit your operations.

Q1: Can the Drill Re-Sharpening Machine handle different drill sizes?

A1: Yes, it supports drill diameters ranging from small to medium sizes, suitable for various industrial applications.

Q2: How does the machine ensure consistent sharpening precision?

A2: It uses advanced grinding wheels and adjustable angles to deliver accurate and reliable sharpening results.

Q3: Is the Drill Re-Sharpening Machine energy-efficient?

A3: Yes, its optimized motor design ensures efficient power consumption while maintaining high performance.

Q4: Can I sharpen drills of unlimited length with this machine?

A4: Yes, the machine accommodates drills of unlimited length, making it versatile for different tools.

Q5: How does this machine help reduce operational costs?

A5: It re-sharpens drills, reducing the need for frequent replacements and lowering overall tool expenses.

Q6: Is this machine suitable for use in high-demand production environments?

A6: Yes, its durability and precision make it ideal for industries with high tool usage and production needs.

Q7: Does the machine require regular maintenance?

A7: Minimal maintenance is needed. Routine cleaning and checking the grinding wheel ensure long-term performance.

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are designed to restore the sharpness and cutting efficiency of drill bits. These machines cater to industries that require high precision and cost-effective grinding solutions. They are suitable for sharpening high-speed steel and tungsten steel drills, ensuring consistent performance and extended tool life.

Both models feature a space-saving design, making them ideal for workshops and manufacturing facilities with limited space. Their lightweight structure allows for easy transportation and setup while maintaining stability during operation. These machines are engineered to fit seamlessly into industrial environments.

The DRM-13 and DRM-20 are equipped with advanced grinding wheels (D13CBN and D20CBN), optimized for accurate and efficient sharpening. The grinding scope for apex angles ranges from 90° to 150°, enabling precise sharpening for a variety of drill types. With a rated speed of 5000 rpm, these machines deliver consistent results with every use.

The DRM-13 supports drill diameters of 3mm to 13mm, while the DRM-20 accommodates larger drills ranging from 3mm to 20mm. This versatility makes them suitable for various industrial applications, from small-scale operations to large-scale manufacturing.

These machines provide an affordable solution for maintaining your tools. By re-sharpening drills instead of replacing them, businesses can significantly reduce operational costs while ensuring tools remain sharp and reliable for extended periods.

| MODEL | Applicable diameter ot the drll | Grinaing scope ot the apex angle | Grinding scope ot the dorsal nom | Grnding wheel | Length of drill | Power | Motor output | Raded speed | Outer dimensions | weight | Normalaccessories | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-13 | φ3~φ13mm | 90°~150° | 0°~12° | D13CBN (SDC Choose) | —— | 220V±10%AC | 250W | 5000 rpm | 290x260x230(mm) | 16KG | Collet φ3~φ13mm(11pcs),Hexagon wrench*2pcs, Chuck group*1 Group,controller*1pcs | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-20 | 中3~φ20mm | 90°~150° | 0°~12° | D20CBN (SDC Choose) | —— | 220V±10%AC | 250W | 5000 pm | 345x160x210(mm) | 19KG | Collet φ3~φ20mm(18pcs),Hexagon wrench*2pcs, Chuck group*2 Group,controller*1pcs | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRM-50 | Taper-shank drillφ13~φ50mm | 118°~180° | 4° | D50CBN | Maximum length 400mm | AC220V | 200W | 2800 rpm | 650*590*350(mm) | 68KG | Jacket for taper shank(4-1#,4-2#,4-3#)one for each, lron wedge block*2pcs,Hexagon wrench*2pcS Chuck group*1Group | ||||||||||||||||||||||||||||||||||||||||||||||||

Grinding wheel: SDC wheels used for tung-sten carbide tools, CBN wheels used for high-speed steel tools.

These Drill Re-Sharpening Machines are a reliable choice for industries looking for efficient and affordable drill re-sharpening solutions. Contact us today to learn how the Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) can meet your tool maintenance needs.

| High Efficiency, Sharp, Durable ● No need to hire professional tool grinding worker ● No need to hire professional programming worker ● One person can operate multiple machines

|

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are designed to restore the precision and cutting efficiency of drill bits. These machines are suitable for a variety of industries requiring reliable performance and cost-effective solutions. Below are the key features and applications of these advanced grinding machines.

The machines are specifically designed to sharpen high-speed steel and tungsten steel drill bits. This compatibility ensures precise and efficient grinding, making them ideal for various industrial applications. Whether you’re dealing with tough materials or standard drill bits, these machines deliver consistent results.

The Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) offer adjustable apex angles ranging from 90° to 150° and back angles from 0° to 12°. These customizable settings enable precise sharpening for different materials and applications, ensuring optimal tool performance.

Both machines are designed for quick and easy operation, allowing users to complete sharpening tasks in just one minute. Their intuitive design eliminates the need for professional tool grinders or programming skills, making them accessible for operators of all experience levels.

The DRM-13 supports drill diameters from 3mm to 13mm, while the DRM-20 accommodates up to 20mm. This wide range of compatibility makes these machines suitable for small to medium-sized drill bits, catering to diverse industrial requirements. The machines also allow for sharpening drills of unlimited lengths, increasing their usability.

These drill re-sharpening machines are widely used in industries such as automotive, aerospace, mold-making, and general manufacturing. Their precision grinding capabilities make them ideal for maintaining drills used in critical applications. By keeping tools sharp and efficient, they help improve productivity and reduce downtime.

By restoring the cutting edge of drills, these machines significantly reduce the need for frequent tool replacements. Their affordable price and ability to be operated by a single person make them a cost-effective solution for businesses aiming to save on operational expenses.

With their combination of advanced features, versatile applications, and ease of use, the Drill Re-Sharpening Machine DRM-13(φ3-013) and DRM-20(φ3-φ20) are the perfect choice for industries looking for precision drill grinding equipment. Contact us today to learn more about these affordable drill re-sharpening machines and how they can benefit your operations.

Q1: Can the Drill Re-Sharpening Machine handle different drill sizes?

A1: Yes, it supports drill diameters ranging from small to medium sizes, suitable for various industrial applications.

Q2: How does the machine ensure consistent sharpening precision?

A2: It uses advanced grinding wheels and adjustable angles to deliver accurate and reliable sharpening results.

Q3: Is the Drill Re-Sharpening Machine energy-efficient?

A3: Yes, its optimized motor design ensures efficient power consumption while maintaining high performance.

Q4: Can I sharpen drills of unlimited length with this machine?

A4: Yes, the machine accommodates drills of unlimited length, making it versatile for different tools.

Q5: How does this machine help reduce operational costs?

A5: It re-sharpens drills, reducing the need for frequent replacements and lowering overall tool expenses.

Q6: Is this machine suitable for use in high-demand production environments?

A6: Yes, its durability and precision make it ideal for industries with high tool usage and production needs.

Q7: Does the machine require regular maintenance?

A7: Minimal maintenance is needed. Routine cleaning and checking the grinding wheel ensure long-term performance.